|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

3M Scotchcast Cable Joints For Flat Low Voltage Power & Control Cables In The Nuclear Industry

By Chris Dodds on 21st April, 2015

The Pile Fuel Storage Pond At Sellafield UK

Originally built in 1948, the pile fuel storage pond located in Sellafield, Cumbria was designed to receive, cool

and decan fuel from the Windscale Piles. The site was later upgraded in the 1950s to allow receipt of spent magnox fuel from the Calder Hall reactors.

and decan fuel from the Windscale Piles. The site was later upgraded in the 1950s to allow receipt of spent magnox fuel from the Calder Hall reactors.

When decanning in the pond ceased in 1962, the pond was continued to be used as a storage facility for fuel, contaminated items and operational waste.

The pile fuel storage pond now contains nuclear fuel, sludge, pond water and intermediate level waste. All of which needs to be safely removed and processed through separate disposal routes.

Pile Fuel Storage - Risk & Hazard Reduction

The programme that has been devised for the Sellafield plant works inline with Nuclear Decommissioning Authority (NDA) objectives which are:

- Progress decommissioning and clean up of nuclear waste

- The delivery of high hazard and risk reduction

- Encouraging the highest standards of health, safety and security are upheld

Pictured: The Sellafield Pile Fuel Storage Pond

The solution that has been put in place for the Sellafield pile fuel storage pond has the objective of safely emptying and decommissioning the Pile Fuel Storage Pond. The six specific aims that have been set out in order to meet this objective are:

- Retrieve sludge to an in-coral pond

- Construct local sludge storage facilities for the short term storage of sludge

- Provide the long term storage of retrieved waste in product boxes

- The recovery of oxide fuel to be reprocessed

- Transfer metal fuel to the fuel handling plant at Sellafield

- Package remaining ILW inventory into safe boxes for long term storage

T&D With 3M - Providing Jointing Solutions In The Most Challenging Of Conditions

T&D were approached with a request for a customised cable joint to replace a section of damaged flat form pilot cable at the Sellafield plant. Typically, cable joints will be installed to replace a section of mechanically damaged cable where the integrity of the cable sheath has been compromised risking water ingress.

The damaged cable was a flat Elettrokkabel M(StD)HOU UL cable - this type cable is used for heavy duty mobile applications. Typical applications include : overhead cranes, hoists, elevators, lifts, festoon lighting garlands and submersible pumps.

Due to the flat-form construction of the area around the cable joint seal there was a need to build-up diameter as 3M Scotchcast LVI-1-PT cable joints are usually installed on round cables. This area of cable should be built up using 3M Scotch 2228 tape.

Water Resistant & Hydrolytic Stability

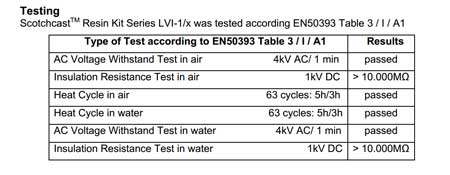

As the cable circuits were located in high humidity area it was crucial that the cable joint specification could demonstrate suitable moisture resistance. All 3M Scotchcast resin cable joints meet the requirements of EN50535 which means the joint is tested after having been immersed in water - 3M recommend LVI-1 Premium Resin Cable Joints utilisng Scotchcast 470W resin.

Pic : 3M LVI-1 Scotchcast Resin Cable Joints - EN50393 Testing Extract

T&D, with the advice of 3M specified the 3M Scotchcast LVI-1/3PT Multi Pair 0.9sqmm Cable Joint. The advice given by 3M was that the solution to be provided was:

"A standard resin joint for pilot and telecom type cable (to accommodate the foil shield) but this is intended for round cable and the customer would have to build up the diameter to make it fit into the mould shell. Recommend 2228 Tape for this. Going by the largest side of the flat cable (30.2mm) I would offer the LVI-1/3-PT".

There are many benefits of using the 3M LVI-1/3PT cable joint including its low failure rate and fully integrated advanced resin delivery system which removes the risk of the resin coming into contact with human skin.

Pictured: 3M Fully Integrated Advanced Resin Delivery System

What Does The Future Hold For Sellafield?

The plan to progressively empty the pile fuel storage pond will reduce the risk and hazard posed by the storage of nuclear wastes within the facility. The first major milestone will the completion of the local sludge treatment plant.

Bulk de-sludging is expected to be completed during the 2015/16 financial year with the completion of the Local Sludge Treatment Plant Export Project expected to be in the 2017/18 financial year.

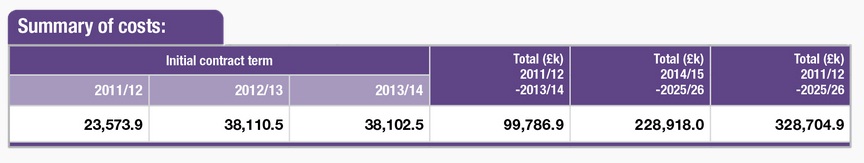

The final stage of the project will be the total dewatering and dismantling of the remaining structure down the base. The cost of this project is substantial with the cost of the project in 2014/15

Pictured: The Cost Of The Sellafield Fuel Storage Pond

Category: LV Cable Jointing & Terminating

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick