|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

Vantrunk SW6 Speedway Cable Ladder Installed at Yemen LNG Project

By Chris Dodds on 20th August, 2012

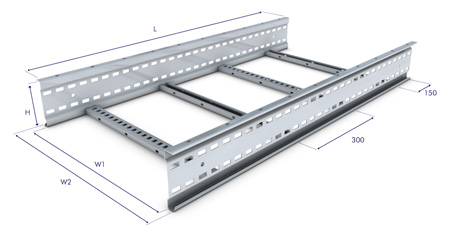

Vantrunk SW6 Speedway Cable Ladder

The Yemen LNG Project comprised of new and existing upstream gas processing facilities including a transfer line linking the two gas processing units, a new main pipeline, which will connect the gas processing facilities to the new liquefaction facilities in Balhaf, and a spur line to transport domestic gas to the Ma’bar area.

Pictured: Yemen LNG Plant

Vantrunk worked with Toyo Kanetsu KK on the 420 Million Cubic Feet/Day Gas Processing Plant to serve the near by Yemen LNG Export Terminal. Vantrunk Supplied SW6 Mild Steel Hot Dip Galv Speedway Cable Ladder and Extra Heavy Duty Cable Tray.

Speedway Cable Ladder SW6 - Finishes & Materials

- GY - Hot Dip Galvanised Vantrunk Extreme Steel

- GX - Deep Galvanised Vantrunk Silicon Rich Structural Steel

- SS - Marine Grade Stainless Steel

- GK - Hot Dip Galvanised Vantrunk Silicon Rich Structural Steel

Pictured: Vantrunk SW6 Speedway Cable Ladder

| Part No. |

No.of Rungs |

Dimensions | Weight | |||

| W | W1 | L | H | |||

| SW6/SL3/150/O | 10 | 150mm | 200mm | 3000mm | 150mm | 21.63kg |

| SW6/SL3/300/O | 10 | 300mm | 350mm | 3000mm | 150mm | 23.79kg |

| SW6/SL3/450/O | 10 | 450mm | 500mm | 3000mm | 150mm | 25.95kg |

| SW6/SL3/600/O | 10 | 600mm | 650mm | 3000mm | 150mm | 28.11kg |

| SW6/SL3/750/O | 10 | 750mm | 800mm | 3000mm | 150mm | 30.28kg |

| SW6/SL3/900/O | 10 | 900mm | 950mm | 3000mm | 150mm | 32.44kg |

| SW6/SL3/1050/O | 10 | 1050mm | 1100mm | 3000mm | 150mm | 34.60kg |

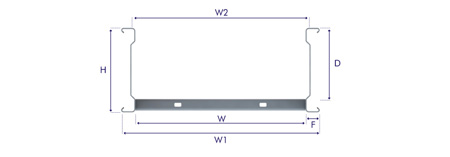

| Height | H | 150mm |

| Loading Depth | D | 125mm |

| Ladder Width | W | 100mm to 1500mm |

| Maximum Internal Width | W1 | W + 14mm |

| Overall Width | W2 | W + 50mm |

| Flange Width | F | 25mm |

Vantrunk Speedway SW6 Cable Ladder Systems

1) Fully slotted cable ladder sides reduces weight - allows ladder to be cut and joined without the need for on-site drilling - accessories can be mounted at any point along the length of the cable ladder run.

2) Unique side wall profiles increases width for cable containment - increases strength and rigidity in side walls.

3) Fully returned edges on side walls and ladder rungs improves safety during handling and minimises damage to cables during cable pulling.

4) Continuous profile for fittings maintains strength in fittings - reduces the need for additional steelwork to support fittings.

5) Unique coupling system matching profiles provide positive location for couplers - design of slot patterns in couplers and side walls minimises slip (a common fault for most slotted cable ladder systems).

6) Rungs located at lowest point on side wall maximises loading depth - no loss of coupler fixings when cutting and joining cable ladders near to rungs.

- Further Reading

Vantrunk Speedway Cable Ladder System Installed at BNG Technology Centre

Vantrunk Speedway SW4 & SW6 Cable Ladder for BTC Pipeline

Invitation

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group : Low & High Voltage Power, Cabling, Jointing, & Hazardous Area Electricals (LV-HV).

Discussion subjects include cable installations, cable jointing, electrical substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Network, engage and promote your profile, company or products with over 10,000 influencers.

Category: Cable Containment LV HV

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick