|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

Roxtec Modules - RM BG & B Modules For Use With Roxtec Cable Transit Frames

By Chris Dodds on 20th February, 2014

Roxtec Cable Transits & Duct Seals

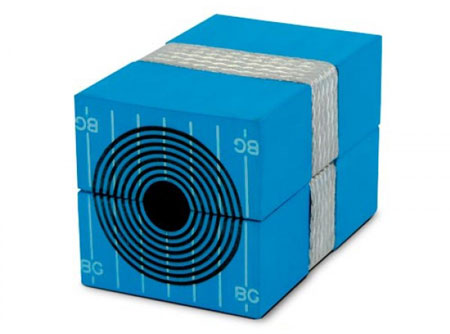

A Roxtec RM sealing module consists of two halves, and has removable layers and a centre core.

Due to the Roxtec Multidiameter technology, one single module can seal a cable or pipe over a span of several different diameters simply by peeling layers from the module halves. The multidiameter technology ensures a perfect fit.

Roxtec RM BG and B module is an integrated environmental sealing system for bonding and grounding applications.

Roxtec RM BG and B modules are for use with armoured/shielded jacketed cables including smooth and corrugated cables such as interlocked and continuous welded metal clad cables or wired and braided cables.

Roxtec RM BG B Sealing System Modules - Installation Instructions

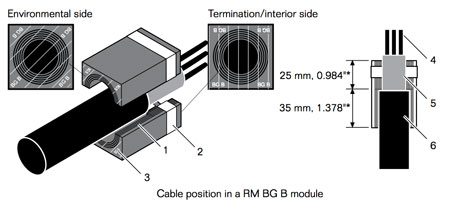

- 1 - Multidiameter – modules adapt to cables and pipes of different sizes through removable layer

- 2 - Bonding/grounding braid

- 3 - Environmental side

- 4 - Conductors

- 5 - Cable armour

- 6 - Outer jacket

* Roxtec RM 90 BG B 30 mm, 1.181"

*Roxtec RM 120 BG B 30 mm, 1.181"

Installation Of Roxtec RM BG B Sealing Module

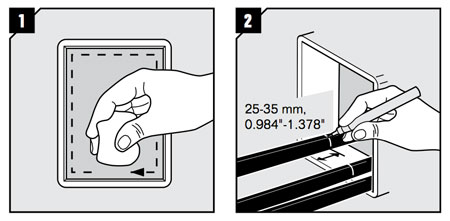

1. Clean the empty Roxtec cable transit frame from paint, dirt etc. to secure good electrical conductivity.

2. On the cable, mark where outer sheath and armour, if applicable, are to be removed.

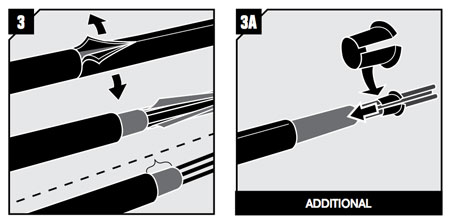

3. Remove the outer sheath and armor/shield with a tool of your choice. Make sure not to damage the cable screen/armor. Remove any protection tape or plastics.

3A. When required for inner conduction protection, fit an anti-short bushing at the end cut of the cable screen/ armour.

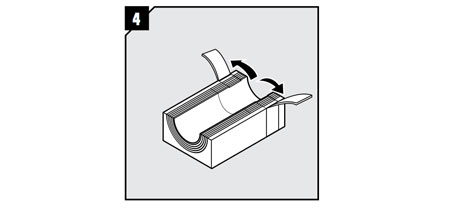

4. Remove the core and fold out the braid on modules that are to hold cable/pipe.

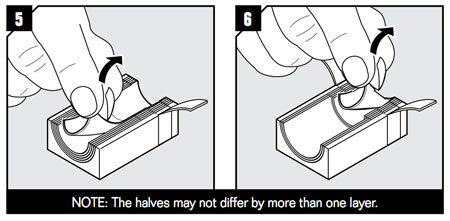

5. Adapt outer layers of Roxtec sealing module to cable/pipe on both module halves.

6. Adapt inner layers to Roxtec sealing module to cable screen / armour/pipe on both module halves.

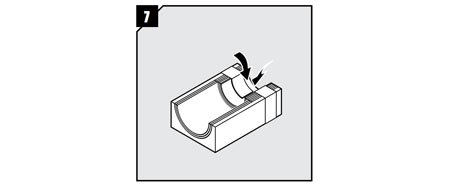

7. Fold the braid tightly inside the Roxtec module.

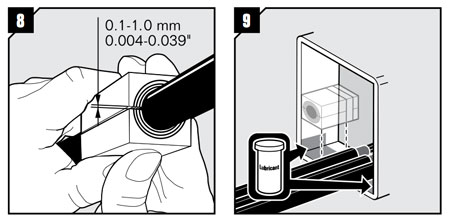

8. Achieve a 0.1-1.0 mm gap between the two halves of the Roxtec module when held against the cable/pipe.

9. Lubricate the Roxtec cable transit frame on the areas that will be in contact with the rubber of the Roxtec modules. Avoid excess lubricant on areas in contact with the braid.

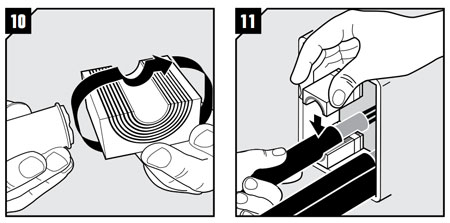

10. Lubricate all Roxtec modules for the cable transit frame thoroughly, both the inside and the outside surfaces. Avoid excess lubricant on the braid.

11. Insert the Roxtec module halves directly on top of the cables. Do not slide them in.

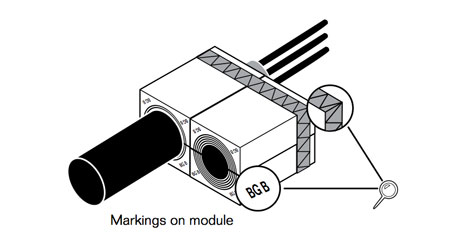

All Roxtec modules should be of the same type in each opening and turned in the same direction. Please note the markings on the face of the Roxtec module.

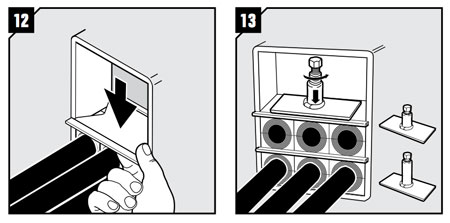

12. Insert a stayplate on top of every finished row of Roxtec modules. Make sure the stayplate is clean.

13. During installation, you can use the pre-compression Roxtec S or L tool to make room.

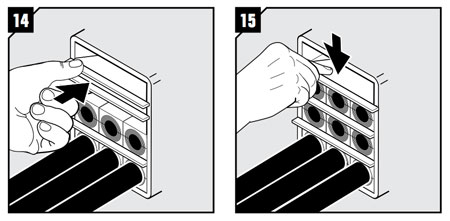

14. Before inserting the final row of Roxtec modules, insert two stayplates together.

15. Separate the two stayplates and insert the final row of modules between the stayplates. Drop the upper stayplate on top of the modules.

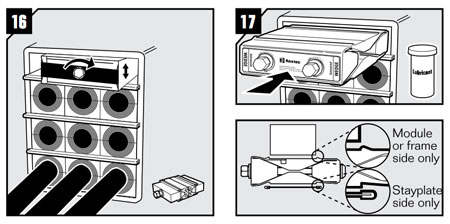

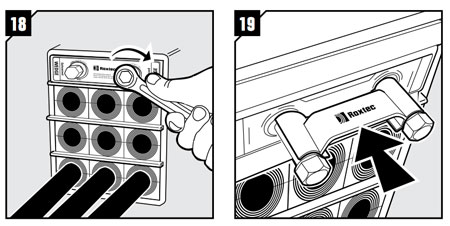

16. Pre-compress by using Roxtec pre- compression wedge.

17. Lubricate the Roxtec wedge on all sides, except front and back, and insert the wedge on top of the cable transit frame (standard position).

18. Tighten the screws until full stop, approx. 20 Nm (15 ft.lb.).

19. Attach the Roxtec wedge clip to the wedge bolts to check that the wedge is properly tightened.

- Further Reading

Invitation

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group : Low & High Voltage Power, Cabling, Jointing, & Hazardous Area Electricals (LV-HV).

Discussion subjects include cable installations, cable jointing, electrical substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Network, engage and promote your profile, company or products with over 10,000 influencers.

|

Category: Cable Transits & Duct Sealing

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick