|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

Retrofilling MV Transformers 11kV-33kV From Mineral Oil To MIDEL 7131

By Chris Dodds on 4th May, 2017

Eden Transformer Oil specialise in the supply and maintenance of electrical oils and can supply MIDEL 7131.

MIDEL 7131 is a fire safe, synthetic ester-based transformer fluid which has been developed as a safer alternative to traditional fluid and dry-type transformers.

Eden Oil also offer services such as on-site purification of MIDEL in service, an oil to MIDEL conversion, or retrofill, service.

MIDEL 7131 Benefits

- Enhanced fire safety.

- Higher environmental protection as MIDEL 7131 is readily and fully biodegradable.

- Increased moisture tolerance over mineral oil and silicones.

- Prolonging longevity of the transformer's solid insulation.

- Lower insurance premiums as a result of improved fire and environment safety.

It is important to note that changing a transformer to MIDEL 7131 is not a simple process of pumping the oil out of the transformer and MIDEL 7131 in.

Steps have to be taken to minimise Oil in MIDEL contamination below 3.5% and also to heat and vacuum the MIDEL to improve air free penetration in to the windings.

Eden have worked with the manufacturers of MIDEL 7131 to tailor our retrofill service to meet their engineers and chemist’s requirements whilst deploying our dedicated MIDEL 7131 plant and hoses to ensure a correctly retrofilled transformer to the highest possible standard.

Benefits of Mineral Oil to MIDEL 7131 Retrofill

- To minimise risk of contamination from oil, use only plant, hoses and equipment that is dedicated to MIDEL 7131.

- Analyse existing mineral oil for Polychlorinated Biphenyls.

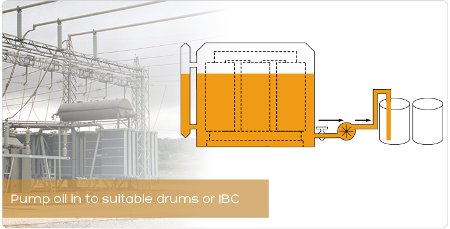

- Remove mineral oil from transformer in to suitable drums or IBCs.

- Remove transformer lid.

- Pump trapped oil from transformer dead spots.

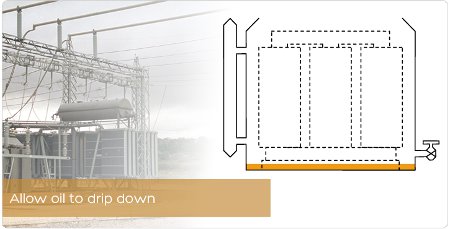

- Allow transformer to drip down.

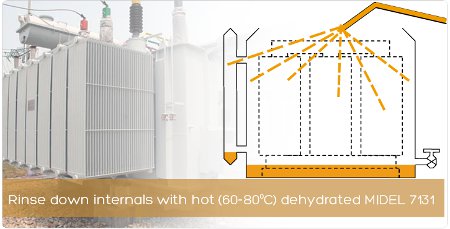

- Rinse down transformer internals with hot (60-80ºC) dehydrated MIDEL 7131.

- Allow further time for transformer to drip down.

- Pump out rinsing MIDEL 7131 (label as contaminated with mineral oil).

- Fit cut lid gasket and refit lid.

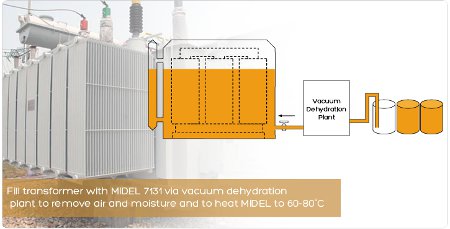

- Fill transformer from the bottom at a maximum speed of 800 litres per hour using vacuum dehydration plant to remove air and moisture and to heat the new MIDEL 7131 to 60-80ºC.

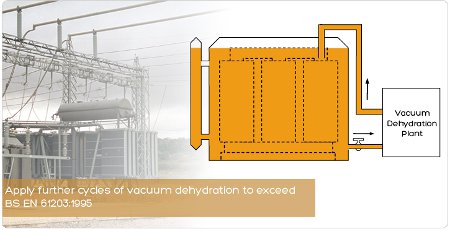

- Apply further cycles of vacuum dehydration to exceed BS EN 61203:1995

- Fit a new desiccant breather.

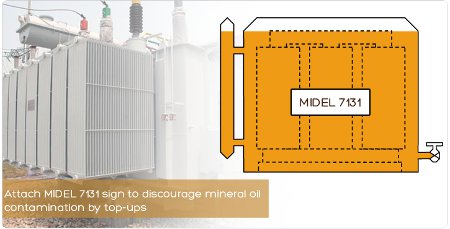

- Fix MIDEL 7131 notice to transformer.

- Draw samples for analysis to confirm completed works meet BS EN 61203:1995.

- Ensure all waste products are removed by a licensed waste carrier to an Environment Agency permitted site.

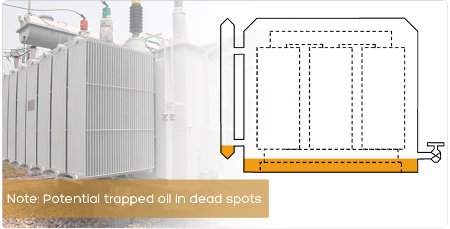

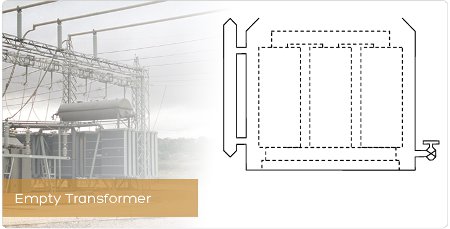

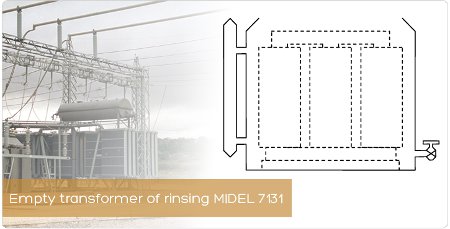

The below images illustrate the M&I approved proceedure for retrofilling MV Transformers from mineral oil to MIDEL 7131:

Note: Potential trapped oil in dead spots

Pump oil in to suitable drums or IBC

Clear trapped oil from dead spots

Allow oil to drip down

Rinse down intervals with hot (60-80ºC) dehydrated MIDEL 7131

Empty Transformer

Allow further time to drip down

Empty transformer of rinsing MIDEL 7131

Fill transformer with MIDEL 7131 via vacuum dehydration plant to remove air and moisture and to heat MIDEL to 60-80ºC

Apply further cycles of vacuum dehydration to exceed BS EN 61203:1995

Attach MIDEL 7131 sign to discourage mineral oil contamination by top-ups

- Further Reading

11kV Cables Jointed, Terminated & Earthed Into MIDEL Filled MV Transformers

The Semicon Screen - A Most Critical Point In Any MV Cable Joint, Termination Or Connector

High Voltage Cable Testing Services & Innovations Up To 200kV

Eden Oil

Since August 1985 Eden have been testing and maintaining the insulating liquids and electrical oils in transformers and switchgear in the United Kingdom, Belgium, France and Germany. Eden provides the end-to-end services and products to maintain transformer oil, MIDEL 7131 and silicon insulating liquid.

Eden can also supply new transformer oil and insulating liquids, desiccant breathers and consumables used for maintaining transformers and switchgear.

Eden Transformer Oil is the only electrical oil supplier in the south of England that also holds the required SR2012 No15 permit for receiving and holding waste electrical oils.

Thorne & Derrick Specialist Electrical Distributor

Established since 1985, T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment - contact us today for a competitive quotation.

Key Products : MV Joints & Terminations, Cable Pulling Products, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Jointing Tools, Feeder Pillars, Cable Duct, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for : 3M, Pfisterer, Nexans Euromold, Elastimold, Catu, Roxtec, Emtelle, Centriforce, Lucy Zodion, Alroc, Hivotec, Cembre, Prysmian, Ellis Patents, ABB & Furse.

Invitation

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group : Low & High Voltage Power, Cabling, Jointing, & Hazardous Area Electricals (LV-HV).

Discussion subjects include cable installations, cable jointing, electrical substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Network, engage and promote your profile, company or products with over 10,000 influencers.

Category: Electrical Equipment HV

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick