|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

Cable Jointing Low Voltage Cables

By Chris Dodds on 30th July, 2013

Low Voltage Cable Jointing.

Top Cable Jointing Tips From Thorne & Derrick.

Correctly fitted cable joint boxes, shells or moulds filled with mixed cold pour compound ensure reliable and water resistant cable joints which should withstand normal service and have an expected life cycle similar to that of the cable.

A key factor in ensuring effective water resistant cable joints is the cable sheath preparation by the LV jointer. Cable sheaths should be clean and well abraded by abrasive cloth or a coarse rasp to enable the cold pour cable jointing compound to bond to the cable jacket polymer.

Cable jointing tools used for sheath abrasion must be kept clean as any contamination of the actual cable sheath by oil or grease will prevent bonding and allow water moisture to ingress into the cable joint and lead to early joint kit failure.

Happy Jointing !

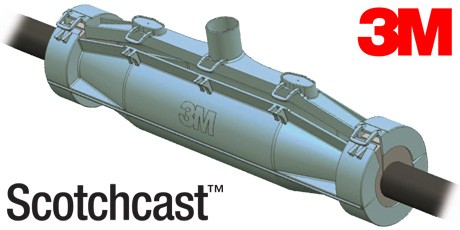

Video - Jointing Low Voltage Cables With 3M Scotchcast Resin Cable Joints :

Category: LV Cable Jointing & Terminating

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick