|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

Extending Asset Life With Condition Monitoring - Guest Blog by EA Technology

By Chris Dodds on 5th January, 2016

T&D are proud to present a new Guest Article from EA Technology's Neil Davies and Paul Blackmore on how to extend the life of assets using condition monitoring.

Extending Asset Life With Condition Monitoring

To understand how to defer asset renewal related expenditure it is worthwhile exploring the underlying drivers for this class of investment. In short, the business case to replace an asset is positive when the cost of renewal is less than the future liability of downside risk associated with retaining the asset in service.

So therefore, it may be possible to defer the requirement for investment if these negative consequences or downside risks can be managed to tolerable levels. Today’s typical electricity distribution network equipment, such as power transformers and switchgear are high cost, long life assets.

Investment in new assets is largely driven by two inter related drivers, i) the requirement to provide new capacity or capability, and ii) the need to maintain existing capability as assets deteriorate from time and use in service.

Uncertainty makes investment decisions difficult. Should a company invest in a multi-million dollar asset if the long term future requirement for that asset is uncertain? In such a business environment the ability to defer investment, particularly renewal investments where there is no impending capacity or capability related driver has practical and financial advantages.

If asset renewal replaces an existing capacity or capability then what is the real driver? The driver is that the investment is needed to prevent the negative consequences of asset failure. For electricity distribution assets this can include safety considerations, the impact on customer service levels of asset failure and ongoing operating costs.

Changing The Probability Of Failure

Risk is commonly defined as the product of consequences and probability of failure. If the optimal replacement time for an asset is a function of risk, then it follows life can be extended by influencing either of these parameters.

Changing the probability of failure requires changing the physical characteristics of the asset, a process typically known as refurbishment. In this discussion we will however focus on the other dimension, changing the consequences of failure through early knowledge of potential asset failure.

Deferring Replacement Investment

Ageing processes from time, environment and usage produce deterioration in electrical equipment that increases likelihood of failure. Failures may be either functional, where the equipment is no longer capable of performing its intended function, or potential, where a latent issue exists that requires further time or circumstances to be realised as a functional failure.

In electrical equipment functional failures, especially those associated with electrical insulation may result in secondary damage that renders the equipment beyond economic repair, or worse, may cause hazards to safety, or significant impacts to customer service levels. Monitoring of asset condition can allow potential failures to be detected before they escalate, providing an opportunity to manage the consequences of the failure therefore influencing risk.

If risk associated with life limiting failure modes can be managed to tolerable levels, then an extension of asset life may be possible.

A Major Cause Of Failure

Partial discharge activity or PD has long been accepted as a major cause of failure of HV/MV switchgear. Partial discharge in HV/MV insulation can be considered to take two forms: i) surface partial discharge and ii) internal partial discharge.

When surface partial discharge is present, tracking occurs across the surface of the insulation, which is exacerbated by airborne contamination and moisture leading to erosion of the insulation. Internal partial discharge occurs within the bulk of insulation materials and is caused by age, poor materials or poor quality manufacturing processes.

If allowed to continue unchecked, either mechanism will lead to failure of the insulation system under normal working stress, potentially resulting in disruptive failure.

Both surface and internal partial discharges may be reliably detected at early stages of development by hand held partial discharge detection instruments combining both ultrasonic and TEV sensors.

One example of such an instrument, the UltraTEV Locator is shown in Figure 1 below. Non-intrusive instruments for the detection of PD are now widely used by many utilities around the world with excellent outcomes.

One large national distribution company reported results where the number of outages due to MV switchgear failure were reduced by 71% over a 5 year period resulting in over 470 fewer failures per year, representing a significant reduction in the consequences of failure and therefore risk.

Figure 1 Example of a combined Ultrasonic and TEV partial discharge detection instrument

Cost And Availability Of Labour

While the use of hand held instruments has been shown to be effective in filtering an asset population for potential failures, this approach does have a disadvantage in that the sampling frequency is limited by the cost and availability of labour to perform the testing.

Some life limiting failure modes may progress rapidly, be intermittent, or dependent upon environmental conditions. This may mean that a large sampling interval will not provide the required risk reduction or confidence that safety related risks are appropriately controlled.

To overcome this problem, condition monitoring equipment can be permanently installed for equipment with a high combination of likelihood and consequences of failure. An example of a continuous monitoring system is shown in Figure 2 below.

Figure 2 Example of a continuous online monitoring system for partial discharge in MV switchgear

Installation and ongoing operation of a continuous monitoring system requires an investment. To establish the business case for such an investment, the potential benefits in risk reduction that the system will provide must be understood. EA Technology’s Condition Based Risk Management (CBRM) provides a methodology to calculate the condition and failure related risk associated with large populations of assets by developing calibrated estimates of each assets probability and consequences of failure.

A quantitative estimated probability of failure (failures /year) is derived from an asset ‘Health Index’ which combines known information relating to the assets age, design, operating environment, operating duty and physical observations of condition.

Application Of Appropriate Criticality Factors

Consequences of failure are evaluated at the individual asset level in financial terms. This is achieved by firstly developing quantified estimates of the average consequences of failure in the dimensions of Network Performance (or production impacts), Safety, Financial, and Environmental impact.

These average consequences are then individualised by scaling up or down to reflect an individual assets operating context through the application of appropriate criticality factors.

To explore the potential benefit for the application of online partial discharge condition monitoring, we have pooled the estimates of failure related risk for a sample population of approximately 3,400 11 kV metal clad switchgear panels. The sample has been drawn from a range of operating environments consistent with those found in both Australia and New Zealand.

By pooling data in this way we are provided with some insight into the spectrum of risk values presented by metal clad switchgear in the region.

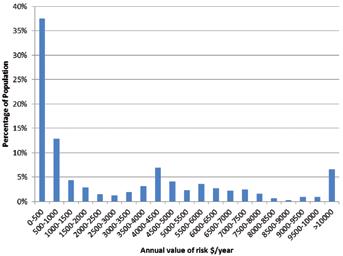

Figure 4 shows a frequency plot of calculated annualised risk values. It should be noted that in all cases the quantum of risk is dominated by the effect of loss of supply or network performance risk which can be highly variable depending on the network configuration and connected customers.

Figure 3 Consequence categories for which consequences of failure are evaluated

The outcome of this process is a measure of asset failure related risk quantified in financial terms. It should be noted that a significant part of risk quantification is evaluating the financial value of loss of electricity supply to customers.

For distribution networks this is approached using a Value of Customer Reliability (VCR) methodology consistent with methods accepted by regulators in Australia and New Zealand. Calculating risk in financial terms makes it possible to use the derived risk values in cost benefit calculations to test the validity or otherwise of various risk management interventions.

Figure 4 Histogram of annual risk for a sample population of metal clad switchgear

Considering Figure 4, it can be seen that the spectrum of risk varies significantly from relatively low values of less than $500 per year to some units with very high values of greater than $10,000 per year. Assets with high calculated risk values are typically ageing oil type switchgear in critical network locations.

While the majority of assets present low risk values, as should be the case, a significant proportion of the population present risk at levels where the addition of continuous online monitoring can be expected to provide a net positive financial benefit and potentially allow these assets to remain in service longer than they otherwise may have been allowed.

Conclusions

In uncertain and challenging business conditions deferral of capital investment to replace ageing high value long life assets is attractive as this minimises the likelihood of acquiring assets that may be stranded or under-utilised.

If the optimum time to replace an asset is when the net present value of tangible and intangible consequences is less than the cost to replace the asset, then life extension may be possible if the consequences of asset failure can be appropriately mitigated.

Condition monitoring and in particular continuous online monitoring can provide such a risk reduction with upfront investment costs substantially lower than equipment replacement.

- Further Reading from EA Technology :

Condition Assessment of HV Cables - Guest Blog by EA Technology

Video Tutorial Masterclass - PD Partial Discharge & Electrical Cable Breakdown

CableSniffer - The Proven Technique for Locating LV Cable Faults

New Paper : "Reducing Failure Rates and Better Management of Underground Cable Networks"

Get the most out of LV Network Planning and WinDebut, check out our two day training course #PowerSkillCentre https://t.co/Ez3IZyiVrf

— EA Technology (@eatechnology) December 22, 2015

Check out our vision for the future following the @MyElectricAve project. https://t.co/mMXisVmPo0 @eatlDaveRoberts pic.twitter.com/DLHitvcDVD

— EA Technology (@eatechnology) December 22, 2015

Video: EA Technology Partial Discharge Podcast

Invitation

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group : Low & High Voltage Power, Cabling, Jointing, & Hazardous Area Electricals (LV-HV).

Discussion subjects include cable installations, cable jointing, electrical substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Network, engage and promote your profile, company or products with over 10,000 influencers.

Category: Electrical Equipment HV

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick