|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

Condition Assessment of HV Cables - Guest Blog by EA Technology

By Chris Dodds on 6th January, 2016

T&D are proud to present a Guest Article from EA Technology's Neil Davies and Paul Blackmore on the importance of assessing the condition of HV cables to reduce network risk which can significantly impact performance.

Of all the major asset classes on electricity networks, HV cables are regularly shown to have a high contribution to overall network risk and significantly impact network performance. Unfortunately they will often have the least amount of available condition data to help manage the risk.

To effectively manage high voltage electricity networks, owners and operators have a very real need to understand the condition of their assets. EA Technology has over 45 years of experience working in the electricity sector to improve network performance and implement Condition Based Risk Management with over 60 global utility clients operating Generation, Transmission and Distribution networks, as well as numerous large private network operators.

From this body of data a common recurring theme extracted from fault data is the high impact that unexpected failure of HV cables has on network performance and cost to an organisation.

When maintained in good condition, underground cable distribution systems provide high security of supply. Failure rates can vary considerably between different organisations, often dictated by issues introduced at the manufacture, installation and operation stages of cable lifecycle and also the amount and impact of third party damage caused by excavation around cable networks.

Cable failure rates can be reduced by eliminating root causes from cable installation for new cables and detecting hidden faults on aged cables by applying partial discharge testing in the maintenance stage.

Cable Termination Failures

A high proportion of reported cable faults and failures occur on cable terminations, typically caused by faulty installation, one example is shown in Figure 1.

The use of non-intrusive handheld PD instruments using Transient Earth Voltage (TEV) and ultrasonic techniques is well established and effective in detecting termination problems and this should be the first thing to introduce in the quest for reducing cable faults. In order to look at the condition of the complete cable and joints away from the terminations requires additional techniques.

Figure 1 Partial discharge caused by incorrect installation found on a cable termination using non-intrusive PD ‘UltraTEV’ instrument

Condition Assessment Of Cables

Pressure testing or Hi-Pot testing has often been used on HV cables, particularly as part of commissioning. Although useful in the commissioning phase it is not a good method for detecting insulation defects or providing useful condition information.

Much more valuable condition data can be gathered through the detection and location of PD activity along the cable route and to a lesser extent through assessing the dielectric strength of the cable system as a whole using tan-delta measurement.

The traditional method for the measurement of PD has been to take the cables off line and energise using a power supply operating at Very Low Frequency (VLF). A typical VLF test set used for PD mapping of HV cables will often have integrated tan delta diagnostic capability so both tests can be carried out during the same session.

While PD measurement is suitable for detecting electrical trees, tan delta measurement provides an indication of the overall health of the insulation. Although it is a bulk measurement which can limit its usefulness, it can detect ageing of the insulation e.g. through the presence of water treeing or impurities.

A significant drawback on the use of the VLF diagnostic testing is that it is time consuming and complex to perform the testing. This tends to limit off-line techniques to more of a reactive test e.g. after failure and repair or targeted at specific circuits under consideration for replacement or overlay. To gain more widespread use of PD testing across the cable network, there has been a trend to explore the application of on-line testing techniques.

Non-Intrusive Detection Of PD On Cables

Once a PD event has occurred through the electrical insulation of a cable, a set of radio frequency current pulses both equal in magnitude but opposite in polarity are seen on the line conductors and the earth conductor. In addition, if a PD event occurs between two phases, the effect of equal magnitude and opposite polarity is seen on the phase conductors that the PD event occurred.

Online PD detection utilises this effect by measuring these pulses using Radio Frequency Current Transformers (RFCTs) placed on the earth sheath of the cable as shown in Figure 2.

There is a very important and practical consideration that needs to be considered when assessing the applicability of taking on-line measurements. If the RFCT is placed over both the line conductor and the earth cable at the same time, the discharge currents are canceled.

The connection must therefore always be made by monitoring the earth cable only, or the line conductor after the earth has been taken off (provided the line current is relatively low).

Figure 2 RFCTs installed on the earth conductor of single-core cables

Dealing With Noise

When carrying out on-line testing with the cable in service a difficulty that will be encountered is noise on the cable earth system. Noise will often occur in the same frequency band as PD signals and will be detected by the RFCT sensor. Simply measuring amplitude can therefore provide false alarms of PD and will only have very limited application.

Simple devices will typically utilise in-built filters to try and overcome the effect of noise e.g. a high pass filter in the 1.4 – 1.8MHz range. This has the effect of blocking much of the noise on the earth system but at the same time reduces the ability of the instrument to detect PD signals far down the cable.

As the current pulses transmit down the conductor and earth from the discharge source, the signals attenuate and ‘flatten’ effectively cutting off the higher frequencies to the point that they are filtered out.

Despite the use of high pass filters, simple measurements can still be prone to false alarms and have not been found to be particularly effective for initial widespread screening of cables for PD.

To improve the diagnostic capability from this simple amplitude-only measurement we need to capture information on the pulse shape and reference captured signals to the 50Hz supply frequency.

Additional processing capability is therefore required, as available in the CableData Collector shown in Figure 3.

Figure 3 Equipment for 3-phase On-line measurement of cable PD

To aid analysis, the equipment makes use of a supply reference or detects a reference from the connected RFCTs. The CableData Collector automatically applies a series of filters during the capture process as well as capturing raw unfiltered data.

With automatic application of filters the data capture process is simple, quick (typically 5 minutes per set of 3 cables), accurate and a nonspecialist function. This ensures all the requisite information required for effective analysis of the data is captured every time.

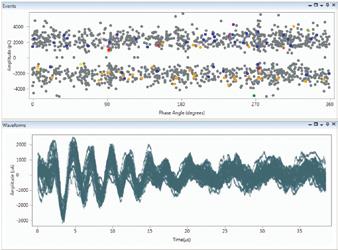

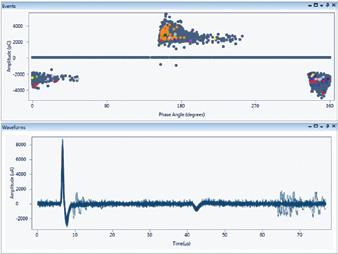

The improved analysis is demonstrated in Figure 4 and Figure 5. Both of these shows similar amplitudes recorded by the instrument of 3000 – 4000pC, safely above the red threshold for XLPE cable. Looking at the waveform and the phase-resolved plot of Figure 4 it is a relatively simple matter to conclude that there is no phase locked signal and the waveform is not consistent with partial discharge.

Figure 5 on the other hand shows as clear phase resolved nature to the activity with a unipolar pulse shape indicative of PD.

Figure 4 On-line measurement of cable measuring noise on the earth system

Figure 5 On-line measurement of cable measuring partial discharge

Without the ability to look at the waveform or reference signals to the 50Hz supply, both sets of these measurements would be classified as serious PD. It is therefore important for any instruments used for screening of cable networks to have this ability to phase reference the data and capture the waveform information.

Without this there will be a high, unacceptable number of false positives which will quickly lead to loss of confidence in the use of on-line technology to detect PD and be a barrier to adoption of a useful tool for the asset manager.

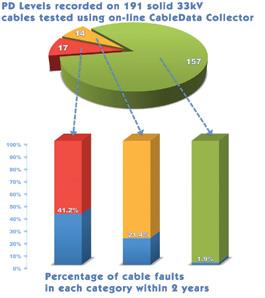

Figure 6 Results from CableData Collector Testing of 33kV Cables

Case Study

An electricity utility with an objective of improving the efficiency of their HV cable investment programme introduced non-intrusive testing of HV cables using the CableData Collector. Figure 6 shows a breakdown of the data collected from a sample of 191 of their 33kV cable circuits. This demonstrates the effectiveness of the instrument in quickly assessing the likelihood of failure of the cables.

To undertake this programme of work and produce these results using off-line techniques would have taken approximately 6 months’ work for 2 skilled technicians in a test van; coupled with the disruption and risk caused by switching out 191 circuits.

The use of the CableData Collector was able to provide a much quicker snapshot on the condition of the cable network and target the more disruptive and costly VLF testing towards circuits where it could produce most benefit rather than on the 80% or more of cables that were in good condition.

Conclusion

On-line partial discharge measurement on cables using the CableData Collector is now being deployed to quickly gather valuable condition information on HV cable networks, an asset class where data is typically sparse. This information can be used to inform capital funds submissions, improves safety, reduces down-time and allows better asset management decisions to be made.

- Further Reading from EA Technology :

Video Tutorial Masterclass - PD Partial Discharge & Electrical Cable Breakdown

CableSniffer - The Proven Technique for Locating LV Cable Faults

New Paper : "Reducing Failure Rates and Better Management of Underground Cable Networks"

Improving #Power Quality positively impacts the bottom line. Download our top tips here: https://t.co/f9vk0l2ruF pic.twitter.com/1o5D7JrzrB

— EA Technology (@eatechnology) November 20, 2015

Did you know we offer technical courses for people in the power industry? https://t.co/vjepNS1WXl #ManchesterHour pic.twitter.com/j5rq7mcxRU

— EA Technology (@eatechnology) November 19, 2015

Video: EA Technology PD Hawk Switchyard PD locator

Invitation

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group : Low & High Voltage Power, Cabling, Jointing, & Hazardous Area Electricals (LV-HV).

Discussion subjects include cable installations, cable jointing, electrical substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Network, engage and promote your profile, company or products with over 10,000 influencers.

Category: Electrical Equipment HV

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick