|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

CATU Bespoke Portable Earthing & Short Circuiting System for Phillips 66

By Chris Dodds on 28th January, 2012

Electrical Safety & Arc Flash

CATU Electrical Safety Equipment

T&D supply CATU portable earthing and short circuiting systems for safe electrical maintenance within high voltage substations.

Working with the High Voltage Distribution Manager at Phillips' 66 Humber Refinery, Thorne & Derrick have designed a customised solution to onsite substation requirements.

Pictured: CATU Portable Earthing & Short Circuiting Kits

The portable earthing kits were designed upon completion of the CATU Portable Earthing and Short Circuiting Check List. From this Thorne & Derrick and CATU worked together creating a bespoke kit to suit the application and 15 portable earthing sets with insulating sticks were ordered.

On this occasion the earth kit contained an assembly kit, copper cable, cable lubricant, 20/30KA earth clamps and also an insulated stick.

Each site standard earthing system comprised of 2.5 metres of M-24-70-S 70sqmm section copper braided cable with transparent silicon insulation, 1x MT-840/1 earth clamp and 1x MT-815-C earth clamp (modified to site installation).

Pictured: CATU Copper Cable & Earth Clamps

The earthing kit complies with International Standard IEC-61230. The cable lugs will be double-crimped to the cable (both to the conductor and the insulation) ensuring mechanical and electrical integrity of the earthing kit. CATU's CF6-095-1-C 0.95m insulating sticks were integral to the earth kit.

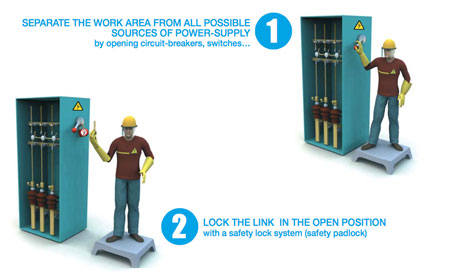

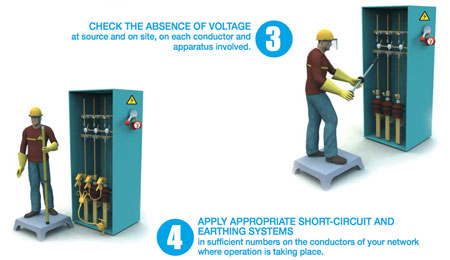

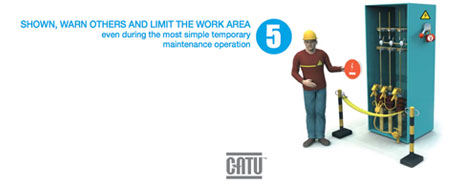

Pictured: Safe Procedures For Working With CATU Short Circuit & Portable Earthing Kits In Medium Voltage (MV) Electricity Substations

Phillips 66 Humber Refinery

Situated on the Humber Estuary at South Killingholme, the refinery came into operation in 1969 with a capacity of about 3 million tonnes.

A unique feature of the refinery is its ability to produce high quality carbon coke from a process using heavy oil residues left over from refining other products. The coke is a vital ingredient in aluminium and steel smelting.

Pictured: Phillips 66 Humber Refinery

A high proportion of North Sea crudes are processed, which are transported to the Humber Estuary by tankers, offloaded at the Tetney monobuoy and piped ashore to Tetney terminal, and then on to the refinery.

In 2004, construction of a Combined Heat and Power plant was completed, adjacent to the refinery, one of the largest, cleanest and most efficient of its type in Europe.

Video: CATU MT-1920 Short Circuiting & Earthing Kit for MV Substations

- Further Reading

Invitation

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group : Low & High Voltage Power, Cabling, Jointing, & Hazardous Area Electricals (LV-HV).

Discussion subjects include cable installations, cable jointing, electrical substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Network, engage and promote your profile, company or products with over 10,000 influencers.

| CATU Low Voltage Short Circuiting & Portable Earthing - Up to 1000v |

Category: Electrical Safety & Arc Flash

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick