|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

Sealing Cables In Substations Using Roxtec Cable Transit System

By Chris Dodds on 15th July, 2013

Roxtec Cable Sealing Systems. Roxtec Cable Transits

Sealing cables into substations must satisfy several substation design criterion: structural and environmental integrity, grounding, fire, protection, waterproof cable sealing and ease of expansion the future cable terminations and upgrades.

Selecting the incorrect cable seal can compromise the environmental integrity of the HV substation, exposing the high voltage cable and substation to flood risk.

There are a number of electrical engineering challenges associated with terminating LV-HV power and control cables in a modular substation.

The first being the number of field cable terminations. In a medium sized industrial substation servicing a large number of motor interconnections, there may be up to 300 or more power and control cable terminations.

The cable terminations must be coordinated with the location of the electrical and control equipment and the skid frame steel members supporting the substation building.

Often, a large number of cables must be terminated in a very limited area leading to cable and connector congestion which can impact worker productivity.

Another challenge associated with terminating field cables is maintaining the environmental integrity of the equipment and the substation building envelope.

This requires that the termination method maintain a vapour-tight weather barrier with a suitable insulation ‘R’ factor value to avoid condensation within the equipment and the building envelope.

The cable termination method should also provide a fire resistant barrier in the unlikely event of a fire.

The cable termination method must accommodate a variety of cable construction configurations and wiring methods.

Cable diameters can vary with some control conductors with diameters of 5mm or less to LV-HV armoured power cables which may have diameters of 100mm or more.

In each case, the cable must be properly secured and grounded in accordance with the local electrical installation codes and requirements.

One often overlooked aspect of the cable termination method is the ability to add cables in the future. The flexibility to easily add additional cable can pay dividends even during the initial installation when design modifications are made late in the installation phase of a project.

A real option for terminating cables into a substation is to use a transit entry frame. The transit frame is welded or bolted to the substation floor at strategic locations where cables will be terminated.

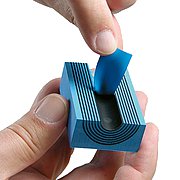

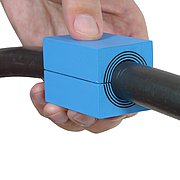

The cables are then pulled into place through the cable transit frames and then sealed using Roxtec Multidiameter cable transit blocks and a mechanical compression wedge.

The cable transit system provides cable retention and provides an environmental, fire resistant and gas tight seal to the equipment and building enclosure.

Cable Transits For Sealing Cable Entries In To Substations

There are several advantages to using a cable transit for sealing cable entry in to a substation. The first being efficiency.

A cable transit allows multiple cables to be pulled at the same time though the transit opening. The large opening eliminates the potential damage to the conductor insulation during installation.

Secondly, the cable transit frame maintains the structural and environmental seal integrity of the floor and allows for a high density and capital efficient installation of cables within a very small footprint.

Also, future expansion capacity is provided for each transit via unused cable blocks which can be easily removed and reinstalled for future cable installation.

Another significant advantage of sealing cables with a cable transit system is the additional room below the building floor and equipment that is provided by the extension of the cable sealing transit frame.

This depth may be customized to a depth equal to the height of the structural steel, and has a standard depth of 60mm.

This additional working space assists with the restrictive bend radius of larger armoured cables and allows for proper cable alignment with equipment configuration.

Cable Transits - Site Installation

The site installation contractor will install interconnecting cables from source to destination via the cable transit openings identified on the cable schedule.

The large opening provided by the cable transit assists the installer pull the cable into place and minimises any damage to the cable conductor insulation.

When all cables for a cable transit are installed, the cables are secured and sealed using the cable transit blocks with stay plates and a mechanical compression wedge.

The cable transit schedules also record the available spare capacity in each cable transit for future growth.

Cables can be easily added without cutting or drilling additional holes, simply by loosening the compression wedge.

- Further Reading

Invitation

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group : Low & High Voltage Power, Cabling, Jointing, & Hazardous Area Electricals (LV-HV).

Discussion subjects include cable installations, cable jointing, electrical substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Network, engage and promote your profile, company or products with over 10,000 influencers.

| White Paper - Roxtec Cable Transits For Sealing Substation Cables |

Category: Cable Transits & Duct Sealing

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick