|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

Prysmian 376AC11 Alumnium Trefoil Cable Cleats Airfreighted To EKB Storage Company In Germany

By Chris Dodds on 30th August, 2012

Prysmian Trefoil Cleats

Prysmian 376AC11

Alumnium Treafoil Cable Cleats

T&D have supplied 1200 of 376AC11 Aluminium Trefoil Cable Cleats to EKB's UK approved Electrical Equipment Vendor. The trefoil cable cleats will provide support and restraint to three single core 41mm OD cables installed in trefoil formation.

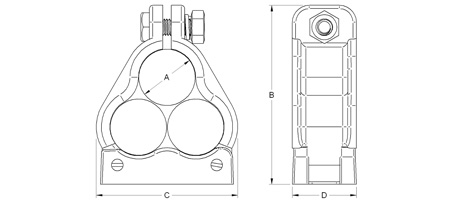

Pictured: Prysmian Aluminium Trefoil Libra Cable Cleats

Prysmian Libra Cleat 376AC Series Features & Benefits

- Prysmian 376AC cleats are for use with cable diameters 24mm to 76mm

- Manufactured from aluminium alloy

- Suitable for single core cables laid in trefoil

- Can be used with all types of cable routes

- Supplied complete with top fastening

- The Libra Cleat is available in plain finish for indoor dry normal industrial use or outdoor unpolluted areas

- Epoxy coated for more hostile conditions

- Operating temperature -60°C to +100°C

- Suitable for use at a maximum system fault level of 30kA rms

| Cable & Cleat Selection | Cleat Details | |||||

| Design No | Cable Diameter | |||||

| Min | Max | Dimensions | Weight | |||

| B | D | C | ||||

| 376AC01 | 24mm | 25mm | 94mm | 38mm | 75mm | 234g |

| 376AC02 | 25mm | 27mm | 97mm | 38mm | 75mm | 241g |

| 376AC03 | 27mm | 28mm | 100mm | 38mm | 75mm | 248g |

| 376AC04 | 28mm | 30mm | 103mm | 38mm | 76mm | 255g |

| 376AC05 | 30mm | 32mm | 105mm | 38mm | 79mm | 269g |

| 376AC06 | 32mm | 34mm | 106mm | 38mm | 83mm | 284g |

| 376AC07 | 34mm | 35mm | 109mm | 38mm | 86mm | 291g |

| 376AC08 | 35mm | 36mm | 113mm | 38mm | 89mm | 298g |

| 376AC09 | 36mm | 38mm | 116mm | 38mm | 92mm | 305g |

| 376AC10 | 38mm | 40mm | 119mm | 38mm | 95mm | 315g |

| 376AC11 | 40mm | 41mm | 122mm | 38mm | 99mm | 319g |

| 376AC12 | 41mm | 43mm | 124mm | 38mm | 105mm | 326g |

| 376AC13 | 43mm | 44mm | 127mm | 38mm | 108mm | 340g |

| 376AC14 | 44mm | 46mm | 130mm | 38mm | 112mm | 354g |

| 376AC15 | 46mm | 48mm | 133mm | 38mm | 114mm | 361g |

| 376AC16 | 48mm | 49mm | 137mm | 38mm | 118mm | 369g |

| 376AC17 | 49mm | 51mm | 140mm | 38mm | 121mm | 376g |

| 376AC18 | 51mm | 53mm | 143mm | 38mm | 124mm | 383g |

| 376AC19 | 53mm | 54mm | 146mm | 38mm | 127mm | 390g |

| 376AC20 | 54mm | 55.5mm | 155mm | 44mm | 133mm | 503g |

| 376AC21 | 55.5mm | 57mm | 158mm | 44mm | 137mm | 517g |

| 376AC22 | 57mm | 59mm | 160mm | 44mm | 141mm | 588g |

| 376AC23 | 59mm | 60mm | 163mm | 44mm | 145mm | 602g |

| 376AC24 | 60mm | 62mm | 165mm | 44mm | 148mm | 617g |

| 376AC25 | 62mm | 63.5mm | 168mm | 44mm | 152mm | 631g |

| 376AC26 | 63.5mm | 65mm | 172mm | 44mm | 156mm | 645g |

| 376AC27 | 65mm | 66.5mm | 176mm | 44mm | 160mm | 666g |

| 376AC28 | 66.5mm | 68mm | 178mm | 44mm | 164mm | 687g |

| 376AC29 | 68mm | 70mm | 181mm | 44mm | 168mm | 716g |

| 376AC30 | 70mm | 71.5mm | 187mm | 44mm | 171mm | 745g |

| 376AC31 | 71.5mm | 73mm | 190mm | 44mm | 175mm | 758g |

| 376AC32 | 73mm | 74.5mm | 193mm | 44mm | 179mm | 773g |

| 376AC33 | 74.5mm | 76mm | 197mm | 44mm | 183mm | 787g |

Single Core Cables Installed in Trefoil Formation

Voltages are induced in the sheath of power cables running in parallel which result in circulating currents flowing in the cable sheaths.

The distances between single core cables running in parallel determine the voltages induced. With single core cables in trefoil formation (touching each other) the distances between the cables are minimum and thus the voltages induced are minimised and hence the circulating currents - the circulating currents cause localised heating.

EKB

Etzel-Kavernenbetriebsgesellschaft mbH & Co KG, headquartered in Hamburg, was established in 2007 as a joint venture between BP, DONG Energy and Gazprom Germania for the purpose of setting up and operating a cavern storage facility in Etzel.

The EKB Storage Facility can store natural gas within 6 salt caverns up to a Working Gas Volume of 500-600 million Nm³. The injection and withdrawal capacities of the facility are expected to be up to 600,000 Nm³/h and 900,000 Nm³/h respectively.

Since April 2nd, 2012 EKB is filling all six caverns simultaneously. The debrining process is running smoothly and without interruptions. EKB expects to finish the First Fill process consecutively in Q3 2012.

OSL Shows Germany the Way Forward 09 July, 2012

OSL are at the forefront of a truly innovative development. A joint venture between BP, Dong and Gazprom, the EKB Project (Etzel-Kavernenbetriebsgesellschaft, ‘Etzel cavern operating company’) is opening up the German market to the transportation of natural gas on an hourly basis to the Dutch and German National Grid.

In North West Germany, underground salt caverns are transformed by drilling deep into the ground and pumping in sea water to dissolve the salt deposits. This creates a cavern of brine with an area of around 300,000 cubic metres. A license has been issued for disposal of the brine in the North Sea, after which the natural gas is stored within the cavern for future transportation via pipeline.

EKB originally hired OSL in 2008 to put in place a technical team for six months, as well as supervising the Front End Engineering Design (FEED). As the project was refined, OSL’s success led to the doubling of this multidisciplined team.

Nick Jones, a Principal Director at OSL’s head office in Hull, said:

“We’ve provided a variety of support services to the EKB Project, covering all technical and commercial aspects. This has provided OSL with a far more in-depth involvement and allowed us to demonstrate our skill at finding the right solution.”

Based in OSL’s Aberdeen office, the project has constant access to the required skills set due to the city’s thriving engineering sector. Within two years of operations, the OSL team involvement had grown to over four times its original size.

Aside from the uniqueness of this project, its equipment perfectly reflects OSL’s skills at problem solving. As opposed to lubricated bearings and dry gas seals, everything is hermetically sealed using magnetic bearings built in Munich; meanwhile, 8Mw electric motors are used, capable of creating pressures of up to 200 bars. This innovative system increases efficiency and makes maintenance far simpler.

Though OSL have used such an arrangement for other gas terminals, it is the first time we have organised it for BP and this specific type of application.

“High-speed, oil free induction motors have proved very interesting and highly effective,” explained Nick. “It’s all about clever thinking, and as a result we have other companies watching us and eagerly taking note. Uniqueness and consistency have been major factors from the start, which certainly gets people’s attention.”

With BP producing over eight billion cubic feet of natural gas every day across their chain, we are proud to be working on such an exciting and valuable addition to their gas storage activity, with the prominent EKB Project being an excellent addition to our already impressive portfolio.

- Further Reading

Prysmian Cable Cleats & Cable Glands (LSF LSOH) - LU London Underground Approved

Cable Glands: Can You Afford The Risk?

Invitation

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group : Low & High Voltage Power, Cabling, Jointing, & Hazardous Area Electricals (LV-HV).

Discussion subjects include cable installations, cable jointing, electrical substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Network, engage and promote your profile, company or products with over 10,000 influencers.

|

Category: Cable Cleats & Cable Ties

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick