|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

How To Find A Single Drip Of Oil In Approximately 12km Of LPOF PILC 115KV Direct Buried Cable

By Chris Dodds on 6th October, 2015

All Images: Douglas Page (Instructor & Cable Splicer at Hydro One Training and Development Services)

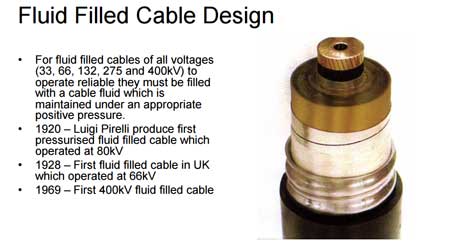

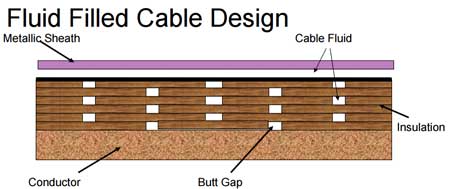

Fluid filled high voltage cables have been used for over 80 years with some circuits installed in the 1930’s still operating successfully today without any deterioration.

The fluid contained within a fluid filled cable has to be kept at a positive pressure under all conditions of loading and ambient temperature change.

Fluid filled cables rely on the presence of pressurised cable fluid to work efficiently - if the circuit suffers an oil leak the cable network is compromised.

The pressure used depends on a number of factors:

- Voltage and size of cable

- The length of the cable

- The route the cable follows

- Whether the cable has a leak

The fluid forms an integral part of the high voltage cable insulation and prevents the formation of voids in the lapped papers around the conductor - also the cable fluid aids the conduction of heat away from the conductor allowing the cable to be run efficiently than a cable without it.

The following photo sequence shows how to find a single drip of oil in approximately 12km of Single Core LPOF PILC 115KV direct buried cable.

LPOF Low Pressure Oil Filled

PILC Paper Insulated Lead Covered

1. Cathodic lead erosion is clearly visible on the EHV power cable - this is usually caused by ground factors such as gas mains, neighbouring cable circuits, water mains etc. The aged underground EHV cable is suffering natural degradation and overtime a deterioration in the cables normal cathodic protection has caused service issues with the cable circuit - the cable becomes the sacrificial anodeand starts to break down.

2. Cable type : Transmission & Distribution Voltage - 115kV LPOF PILC Single Core.

3. LPOF EHV cables are monitored by gauges and pressurized by pre-pressurized tanks with internal baffles, that expand and contract with the cable, maintaining a constant pressure. If the pressure cannot be maintained, an alarm is triggered.

4. To find the oil leak in 10, 15, 20, or 100km of cable, it all starts the same way. Find the approximate centre of the cable circuit, excavate safely and install a cable freeze.

5. Very similar to a pipe type freeze, the coil must be installed on the bare lead.

6.

7. Along with a freeze, to monitor the temperature, the EHV jointer/splicer must install thermocouple temperature monitors which consist of two conductors of dissimilar metals that react to the temperature change differently allowing the monitors to display the actual temperature.

8. Then the freeze is insulated by the EHV cable/splicer.

10.

11. Once the freeze has been initiated, the gauges are monitored, the side that loses pressure, is flagged and deemed the side that requires further attention.

12. Freeze pit - once the leak has been narrowed to 50-100m length, the final excavation begins. Until signs of leaking cable oil are found.

14. After a lengthy search, this is what you are looking for, although opinions vary, constant drip can yield various amounts of accumulation. Some say it could fill a bathtub in 72 hours.

15. Once located a temporary EHV cabl repair is made, while environmental remediation is done.

16. "Tinning" of the cable repair, so the lead will adhere to the cable.

17. The EHV cable repair is complete - after this the jointer must solder a copper lead connected to a sacrificial "anode" that erodes before the cable.

- Further reading

EHV Cable Splicing - 115kV Stop Joint (Taped) Flickr Album

Masterclass : 230kV Pipe Type Pothead Replacement /Cable Freeze

Photoblog - Water Treeing in High Voltage Cables : A 230kV HPPT Termination Repair

Thorne & Derrick Specialist Electrical Distributor

Established since 1985, T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment - contact us today for a competitive quotation.

Key Products : MV Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Jointing Tools, Feeder Pillars, Cable Duct, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for : 3M, Pfisterer, Nexans Euromold, Elastimold, Catu, Roxtec, Emtelle, Centriforce, Lucy Zodion, Alroc, Hivotec, Cembre, Prysmian, Ellis Patents, ABB & Furse.

Invitation

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group : Low & High Voltage Power, Cabling, Jointing, & Hazardous Area Electricals (LV-HV).

Discussion subjects include cable installations, cable jointing, electrical substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Network, engage and promote your profile, company or products with over 10,000 influencers.

| Protect The Value Of Your HV Fluid-Filled Cable Network - Nexans |

Category: Cable Jointing - PhotoBlog

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick