|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

ATEX Approved Cable Conduit for Hazardous Areas - PMA Ex-System

By Chris Dodds on 7th August, 2012

Hazardous Area Electrical Equipment

ATEX Approved Cable Conduit for Hazardous Areas

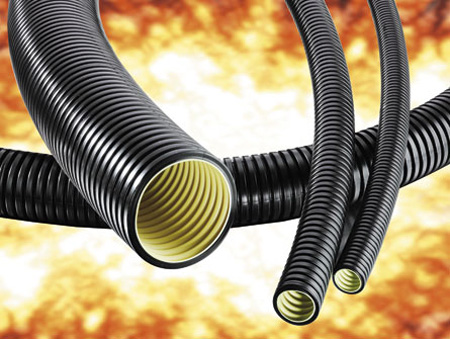

PMA Ex-System XESX Three Layer Corrugated Conduit

PMA’s polyamide cable conduit products present a range of benefits, including a significantly easier installation.

ATEX certified cable conduit contains products made of specially modified, electrostatic load discharging polyamide material for use in explosions endangered zones 1/2 (gas) and 21/22 (dust) according to ATEX 137. The cable conduit system technology is based on the PMA protection system for highest requirements proven for more than 30 years.

PMA has developed a specifically modified, electrical discharging material, the Ex-system range therefore will not act as an ignition source. With a range of cable conduit fittings that can go from flexible to solid steel, it’s ideal for going around corners, can be adapted to suit any application and is suitable for use in dusty environments.

Tony Hollands, national sales manager of Swiss cable manufacturer PMA-UK said: "The system technology is based on the PMA cable protection system for highest requirements proven for more than thirty years. The new ATEX approved hazardous area range means PMA products can be used across an even broader range of applications – ideal for use in breweries where hops could cause ignition and places where potentially hazardous environments exist such as refineries, power stations, paint shops and petrol stations."

|

Application |

|

|

Material |

|

|

Characteristics |

|

|

Temperature Range |

|

|

Specifications |

|

|

Approval |

|

|

Compatible With |

|

|

Colour |

|

| Order No. | Conduit Size | Rec. Fitting Thread |

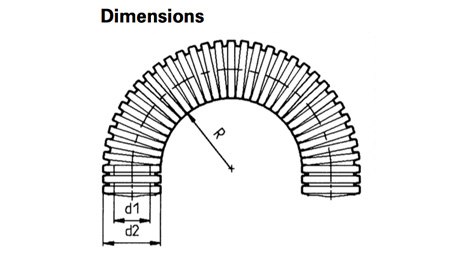

Dimensions |

Weight | |||

|

d1 |

d2 |

stat. R. |

dyn. R. |

||||

|

PMA XESXT-10BY |

10 |

M12 / M16 |

9.2mm |

12.8mm |

25mm |

65mm |

3.0kg/100m |

|

PMA XESXT-12BY |

12 |

M16 / M20 |

11.8mm |

15.6mm |

30mm | 70mm |

4.2kg/100m |

|

PMA XESXT-17BY |

17 |

M20 / M25 |

15.2mm |

21.0mm |

35mm | 85mm |

7.0kg/100m |

|

PMA XESXG-23BY |

23 |

M25 / M32 |

22.0mm |

28.5mm |

40mm | 110mm |

10.5kg/100m |

|

PMA XESXG-29BY |

29 |

M32 / M40 |

27.5mm |

34.4mm |

50mm | 130mm |

14.0kg/100m |

|

PMA XESXG-36BY |

36 |

M40 / M50 |

35.8mm |

42.4mm |

60mm | 180mm |

18.5kg/100m |

|

PMA XESXG-48BY |

48 |

M50 / M63 |

46.8mm |

54.4mm |

70mm | 220mm | 25.0kg/100m |

Invitation

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group : Low & High Voltage Power, Cabling, Jointing, & Hazardous Area Electricals (LV-HV).

Discussion subjects include cable installations, cable jointing, electrical substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Network, engage and promote your profile, company or products with over 10,000 influencers.

|

Category: Hazardous Area Electricals & Lighting

Sort by Category:

- #ThrowBackThursday

- 3M Scotch Tapes

- ABB Power Products

- Business

- Cable Accessories

- Cable Cleats & Cable Ties

- Cable Containment LV HV

- Cable Crimping & Cutting Tools

- Cable Jointer Training Courses

- Cable Jointing - PhotoBlog

- Cable Labelling & Marking

- Cable Laying & Cable Pulling

- Cable Transits & Duct Sealing

- Company Updates

- Earthing & Lightning Protection

- Electrical Equipment HV

- Electrical Equipment LV

- Electrical Safety & Arc Flash

- Exports

- Flexible Conduit Cable Management

- Hazardous Area Electricals & Lighting

- HV Cable Jointing & Terminating

- LV Cable Jointing & Terminating

- Nexans Euromold Cable Accessories

- Plugs & Sockets

- Power Distribution & Feeder Pillars

- Prysmian FP Cables

- PV Solar Farms

- Rail

- T&D History Blog

- Terms & Conditions of Sale & Purchase

Tweets by @ThorneanDerrick