|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

Emtelle HDPE Sub-Duct - Fibre Optic & Power Cable Duct

Emtelle HDPE Sub-Duct - Fibre Optic & Power Cable Duct

1 EMTELLE CABLE DUCT : HDPE SUB-DUCT GENERAL

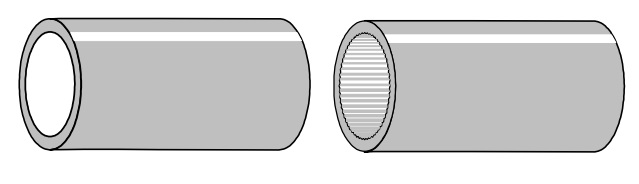

1.1 This document defines single continuous cable duct (sub-duct) made from high quality HDPE, according to paragraph 2.1. It features a bonded low friction dry liner, to enable easy placement of fibre optic and power cables of suitable OD.

1.2 HDPE cable duct (sub-duct) is supplied in coils or on returnable drums (wood or metal)

1.3 The finished cable duct (sub-duct) shall be free from cracks, holes, foreign inclusions or other defects that would impair its performance. It shall be smooth walled inside and out and conform to the requirements of this document. A ribbed internal surface is available on request.

1.4 The finished cable duct (sub-duct) shall be capped ensuring the ends are watertight to prevent the ingress of contamination or foreign bodies likely to cause problems when cabling.

1.5 Cable duct (sub-duct) is available with a standard 8kN pull-rope pre-installed. This may be called ‘rope-in-duct’.

Pictured: Emtelle HDPE Sub-Duct - Fibre Optic & Power Cable Duct

2 EMTELLE CABLE DUCT : HDPE SUB-DUCT RAW MATERIALS

2.1 The tensile strength of the polyethylene stated by the supplier for cable duct (sub-duct) shall be no less than 23MPa.

2.2 The derived density of the cable duct polyethylene shall be not less than 0.95 g/ml when determined in accordance with Appendix B of BS 3412 Method B5.

2.3 The melt flow rate of the cable duct polyethylene compound shall be less than 0.4g/600s when measured in accordance with ISO 1133 Method 720 Test condition 4.

2.4 The cable duct (sub-duct) polyethylene shall be uniform in colour and free from foreign matter.

2.5 Both the polyethylene compound and the dry lubricant of the cable duct shall be protected against thermal degradation such that adequate stabilisation is imparted during processing of the material.

2.6 The cable duct (sub-duct) polyethylene compound shall be adequately protected against ultraviolet degradation in accordance with ISO 877: Method 550B, normal daylight. Performance is based on maximum 6 months storage outdoors.

3 EMTELLE CABLE DUCT : HDPE SUB-DUCT DIMENSIONS

3.1 The cable duct (sub-duct) shall have dimensions (mm) as per the table below.

3.2 Ovality of the cable duct (sub-duct) is the amount the greatest diameter exceeds the diameter at 90° to it, (at one position) divided by the average diameter. It is expressed as a percentage.

a) On the extrusion line of the cable duct (sub-duct) (before the drumming/coiling operation): The ovality shall not exceed 3% (ducts up to OD 40mm). For ducts over nominal 40mm, the ovality shall not exceed 5%.

b) Coming off the drum or coil: The cable duct ovality shall not exceed 7% (ducts up to OD 40mm). For cable ducts (sub-ducts) over nominal 40mm, the ovality shall not exceed 10%.

3.3 The weight (mass) of the cable duct (sub-duct) shall be nominally as stated in the table

4 EMTELLE CABLE DUCT : HDPE SUB-DUCT PERFORMANCE

4.1 TENSILE: The cable duct (sub-duct) shall withstand the stated axial load when applied at 100mm/min to a 500mm gauge length. The elongation due to this load shall not exceed 5%.

NB: The expected tensile ‘yield’ load causes total failure of the duct. ‘Yield’ load is not a safe working load. At this load, the cable duct (sub-duct) has normally elongated by around 10%, and then continues to elongate to failure.

4.2 a) INSTALLATION of DUCT: We recommend that installation tension does not exceed that specified in the previous table, and that correct installation procedures are followed. Pulling cable duct (sub-duct) causes temporary elongation, which reduces when unloaded. After pulling and before cutting or connecting the duct, allow suitable relaxation time, ideally 24 hours or more.

b) INSTALLATION of Cable into cable duct (sub-duct): Use emtelle recommended methods. Do not exceed blow pressure listed below, or the duct may suffer deformation.

4.3 STIFFNESS of each cable duct (sub-duct) at 5% deflection shall exceed that stated below. (Test to ASTM 2412)

4.4 COMPRESSION: The load expected to give 15% deflection on a 200mm length is given. (to EN50086-2-4)

4.5 IMPACT: All cable duct (sub-duct) shall withstand (ie no cracks) a 15J impact at -5°C when tested to EN 50086-2-4.

4.6 COIL SET: When 50m of cable duct (sub-duct) is laid out and allowed to relax, the central part, excluding ends, shall lie substantially straight.

4.7 FRICTION: The frictional force (horizontal) on a standard pull-rope shall be no greater than 390N when lifting a 25kg mass (vertical) at a speed of 0.5m/min. The cable duct sample containing the rope shall be 5m long, and include a 450° loop of diameter 0.75m. .

4.8 BENDING: Minimum recommended bend radius is as stated. If temp is below 5°C, MBR is greater, as stated. Do not go tighter than the MBR. Remember that the greater the installed bend radius, the less stress will be induced in the cable duct, and the easier that cables will blow or pull around the curve.

**Barrel diameters for supply may be slightly tighter than this.

4.9 MARKING: Unless otherwise requested, the cable duct shall be marked as below at one metre intervals:

* Incremental metre-mark

* Manufacturer’s product code

* Production date

* Size of duct

* Customer name and / or other special designations

* (Colours and / or stripes are also available on request)

Underground Cable Ducting

Underground Cable Ducting