|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

Exothermic Welding

Kingsmill Kingsweld

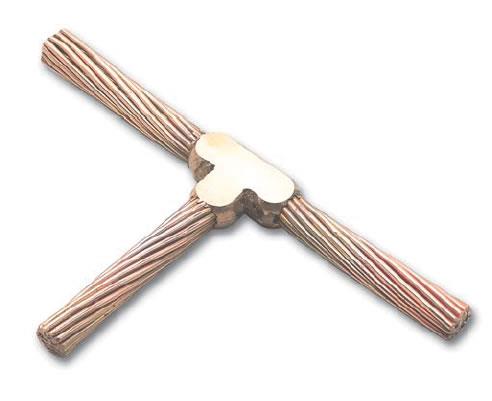

The Kingsweld Exothermic Welding electrical connection process is a simple, efficient method of welding copper to copper or copper to steel.

No outside source of power is required when using exothermic welding connections - Kingsweld exothermic welding connections use the high temperature of reaction of powdered copper oxide and aluminium.

Pictured: Kingsmill Exothermic Welding

The exothermic welding reaction takes place in a semi-permanent graphite mould which endures for a minimum of 50 welds if properly handled.

Exothermic welding takes seconds, therefore the total amount of heat applied to the conductors or surfaces is considerably less than that employed in brazing or soldering - this is an important factor when welding to insulated cables or thin wall pipe.

Exothermic welding is ideal for field use since it is light and portable and requires no outside power source - it requires very little time or skill to obtain an efficient, maintenance free exothermic welding connection.

T&D UK can provide contractors with certified Exothermic Welding training.

Kingsweld exothermic welding equipment is suitable for all types of electrical connection including cable to cable, cable to ground earth rod, threaded stud to steel surface, cable to steel surface, cable to lug or busbar, busbar to busbar, bat to steel surface and cable to rail.

Kingsweld Exothermic Welding Connections

Kingsweld exothermic welding connections are molecular welds - the weld metal has the same melting point as copper. Because of these factors along with the increased cross section of the welding connection, Kingsweld exothermic welding connections:

- Will not be affected by high current surges - tests have shown that the electrical conductor will melt before the exothermic welding connection when subjected to high short-circuit current.

- Will not loosen or corrode at the point of weld - there are no contact surfaces or mechanical pressures involved. Kingsweld exothermic welding connections become an integral part of the conductor.

- Have a current carrying capacity equal to or greater than that of the conductors.