Zone 1 & Zone 2 Stainless Steel Enclosures & Junction Boxes – ATEX Hazardous Area

Zone 1 & Zone 2 Stainless Steel Enclosures & Junction Boxes – ATEX Hazardous Area

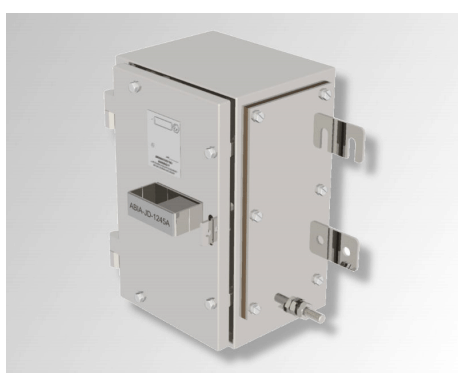

Abtech SX stainless steel electrical enclosures and junction boxes are ATEX certified and suitable for Zone 1 and Zone 2 hazardous areas.

Abtech SX enclosures are available in 14 sizes manufactured from stainless steel – 11 enclosure sizes are available in depths of 140mm or 200mm and 8 sizes are available in depths of 140mm, 200mm or 300mm.

The Abtech SX stainless steel range of hazardous area enclosures feature a high level of ingress protection (IP66/67) specifically designed to meet the demands of onshore and offshore environments with Zone 1 and Zone 2 locations. IP68 enclosures are also available for depths up to 120 ft to special order.

Stainless steel enclosures can be fitted with removable cable glands plates and a mild steel option (Abtech MSX) is available with a range of RAL colour selections.

Zone 1 & Zone 2 Hazardous area

Stainless Steel Enclosures & Junction Boxes

Abtech SX Features

Junction Boxes & Enclosures

- Wide Operating Temperature (-70° Celsius to +175° Celsius) (-94°F to + 347°F)

- IP68 Ingress Protection

- Fire Resistant Enclosures To IEC331

- Corrosion Resistant Stainless Steel Enclosures

- Zone 1 & Zone 2 Hazardous Area Certified By ATEX

- High Strength 2mm Thick Stainless Steel

Temperature Rating

- Hazardous Area: -50°C to +175°C

- Non Hazardous: -60°C to +200°C

Zone 1

A hazardous area location according to ATEX in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

Zone 2

A hazardous area location according to ATEX in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, persists for a short period only.

ATEX Explained

The ATEX Directive consists of two EU directives describing the type of equipment and hazardous area location within a potentially explosive atmosphere. ATEX originates its name from the French title of the 94/9/EC directive: Appareils destinés à être utilisés en ATmosphères EXplosibles.

Cable entries can be drilled in the enclosure or junction box door, sides or via the cable gland plates – cable entries can also be drilled through the rear face of the stainless steel enclosure (EEx’e’ hazardous area versions).

The hazardous area enclosures include a hinged, lift-off door secured to the junction box using 4 captive stainless steel screws which also maintain the correct compression on the gasket.

Electrical Enclosure Junction Box Accessories

Full width, full height cable gland plates |

Earth stud fitted to door and cable gland plates |

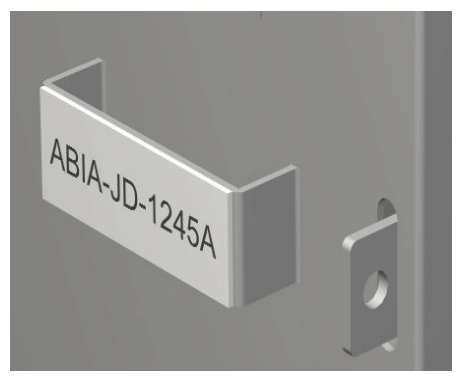

Label bracket welded to electrical enclosure door |

Electro-polished stainless steel junction box surface |

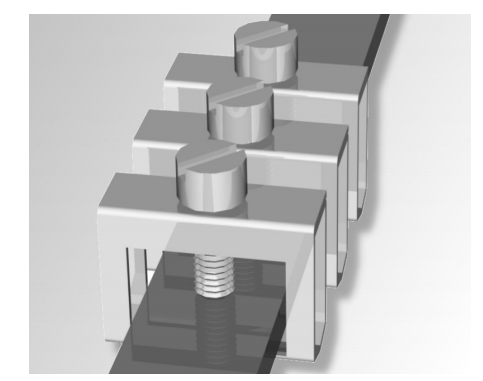

Internal earthing bar (can be fitted with clamps) |

Electrical enclosure mounting plates suppled |

Hazardous Area Certification

Hazardous Area Enclosures: Intrinsically Safe Junction Boxes

Abtech SX enclosures are certified according to leading hazardous area classifications including:

- ATEX & IECEx (Zone 0, 1 & 2; Zone 20, 21 & 22)

- CSA Ex e (Class 1 Zone 1 & Zone 2)

- FM AEx e(Class 1 Zone 1 & Zone 2)

- TR CU Ex e (Zone 1 & Zone 2)

- NEMA 4X (CSA, UL & FM)

- Class 1 Division 2

The range can be supplied with a number of certificates:

- ATEX EEx‘e’ to BS EN 50019 (Zone 1 & 2) EEx‘nA’ to BS EN50021 (Zone 2)

- NEMA 4X (CSA, UL & FM Class 1, Div 2)

- IEC Ex

- GOST

T&D, The Explosive Atmosphere Experts, provide a single-source capability for the most extensive range of Electrical, Mechanical, Process & Instrumentation Equipment suitable for hazardous area locations.

- Zone 1 Hazardous Area Lighting

- Zone 2 Hazardous Area Lighting

- Enclosures, Motor Starters & Isolators

| Hazardous Area Coding & Zones | Zone 0 | Zone 20 | Zone 1 | Zone 21 | Zone 2 | Zone 22 |

| Ex e | ♦ | ♦ | ♦ | ♦ | ||

| Ex ai Intrinsic Safety | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| Ex ab | ♦ | ♦ | ♦ | ♦ | ||

| Ex op is | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| Ex nA | ♦ | ♦ | ||||

| Ex nR | ♦ | ♦ |

Abtech SX stainless steel enclosures are certified according to international hazardous area classifications including UL, CSA, IEC Ex, ATEX, FM, InMetro and TR CU.

Hazardous Area Electrical Enclosures & Junction Boxes

Abtech SX Junction Boxes Selection Table

If in doubt, please contact T&D for specification support and selection advice about hazardous area junction boxes and enclosures.

| Abtech Part Number | Width (mm) | Height (mm) | Depth (mm) | 140mm Depth | 200mm Depth | 300mm Depth | Gland Plates (on any or all four sides) | EP – Electro-Polished External Surfaces (Abtech SX only) | LB – Label Bracket Welded to Door | ES – Earth Stud Fitted to Door & Gland Plates | EB – Internal Earthing Bar | BD – Breather Drain | TP – Tamperproof Lid Fixing Screws | MP – Component Mounting Plate (Steel / Stainless Steel) | RF – RFI Protection |

| SX45 | 114 | 114 | 51 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ||||||

| SX64 | 102 | 152 | 63 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ||||||

| SX66 | 152 | 152 | 102 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |||

| SX0 | 152 | 229 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ||

| SX0.5 | 184 | 274 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ||

| SX1 | 234 | 324 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ||

| SX1.5 | 306 | 306 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |

| SX2 | 372 | 324 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |

| SX3 | 372 | 448 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |

| SX4 | 372 | 510 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |

| SX5 | 510 | 510 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |

| SX6 | 510 | 780 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |

| SX7 | 650 | 950 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |

| SX8 | 800 | 1250 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

Abtech SX Stainless Steel Electrical Enclosures & Junction Boxes – Zone 1 & Zone 2

Fire Resistant Enclosures

BS 6387:2013

Abtech SX enclosures and junction boxes are suitable for fire resistance and fire protection applications and when fitted with ceramic terminals meet the requirements of IEC 331 (750°C for 3 hours) and also BS6387/1983 (950°C for 3 hours).

- BS6387: test method for resistance to fire of cables, enclosures and junction boxes required to maintain circuit integrity under fire conditions.

Stainless Steel Enclosures

Abtech SX enclosures are manufactured from type 316 stainless steel – excellent corrosion resistance including pitting and crevice corrosion in the oil, gas and petrochem industries and offshore high-saline installations.

Earthing

Abtech SX enclosures are effectively earthed using an internal/external earth stud fitted as standard which can be connected to the terminal mounting rail or component mounting rail. Earth studs can be fitted to the door and gland plates and rail mounted earth terminals or proprietary earth bars can be installed within the electrical enclosures.

With international hazardous area classifications, including ATEX, Abtech SX stainless steel junction boxes and enclosures are suitable for onshore and offshore installation in both Zone 1 & Zone 2 hazardous area locations. T&D provide pre-assembled terminal enclosures for use as hazardous area lighting, power, heat tracing and instrument junction boxes with increased safety, intrinsically safe and flameproof explosion protection methods – we can custom supply high voltage enclosures for 3.3kV, 6.6kV, 11kV and 33kV networks.