11kV Joints

11kV Joints | 3 Core XLPE EPR PILC PICAS High Voltage Cables | Heat Shrink

Thorne & Derrick | Distributed from Stock | Approved Supplier | UK & Export Sales

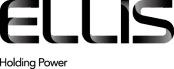

Cable Joints

HV cable joints are suitable for medium/high voltage (MV-HV) 11kV 3 core XLPE, EPR and PILC/PICAS insulated cables.

Heat shrink cable joints suit 11kV cables with 35sqmm – 300sqmm 3 core conductors (copper or aluminium) – this includes steel wire armoured (SWA) cables with XLPE insulation and wire braided cables with EPR insulation.

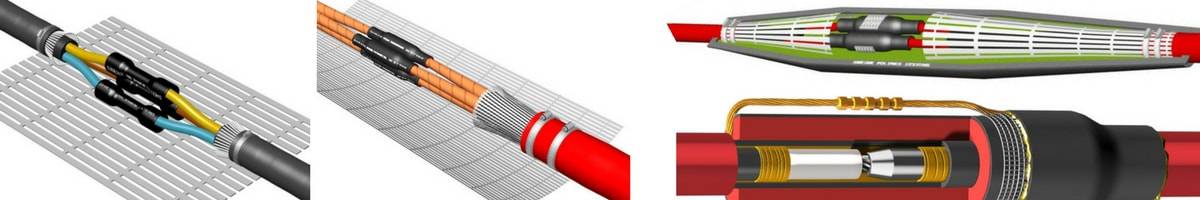

Shrink Polymer Systems 11kV cable joints are tested to CENELEC standards HD 628 S1 and 629.1 S2:2006 encompassing VDE 0278 and IEC 60502 – heat shrink joints are smooth profile design ideal for confined spaces, direct burial underground in cable trench and vertical jointing of cables for medium/high voltage cables.

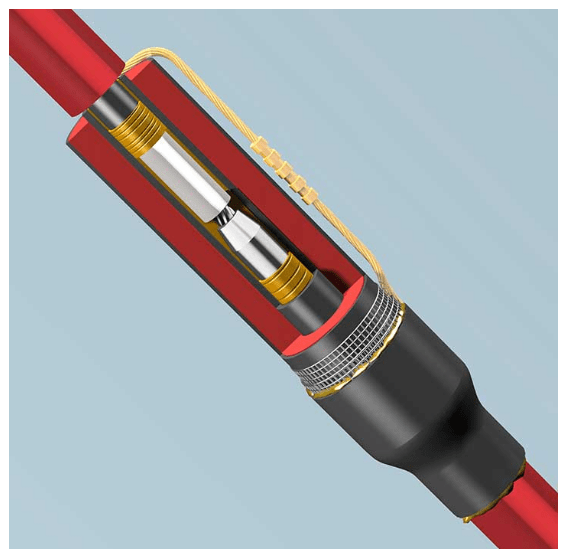

Resin Joints – High Voltage & Hazardous Area

11kV joints for 3 core power cables are also available with optional resin and shell encapsulation for additional mechanical protection for underground cable joints.

For jointing 11kV medium/high voltage cables in hazardous areas, including Zone 1 & Zone 2 according to ATEX Directive, where soil conditions or atmospheric conditions are contaminated with corrosive hydrocarbons and flammable gases the heat shrink or cold shrink cable joints can be supplied with flame and hydro carbon resistant Scotchcast 1402FR resin.

Cable Joints – LV MV HV joints suitable for all cable construction, arrangement and installation requirements from 6.6kV, 11kV up to 33kV.

Selection Table for 11kV Cable Joints | Straight & Transition Cables

| 11kV Cable Joint – Part Code | Conductor Size | Cable Types |

| SPAJ 12U 35-70-3 | 3 Core 35-70sqmm | 11kV XLPE PILC PICAS |

| SPAJ 12U 95-185-3 | 3 Core 95-185sqmm | 11kV XLPE PILC PICAS |

| SPAJ 12U 185-300-3 | 3 Core 185-300sqmm | 11kV XLPE PILC PICAS |

| SPAJ 12X 35-70-3 | 3 Core 35-70sqmm | 11kV XLPE |

| SPAJ 12X 95-185-3 | 3 Core 95-185sqmm | 11kV XLPE |

| SPAJ 12X 185-300-3 | 3 Core 185-300sqmm | 11kV XLPE |

| SPAJ 12PX 35-70-3 | 3 Core 35-70sqmm | 11kV XLPE/PILC |

| SPAJ 12PX 95-185-3 | 3 Core 95-185sqmm | 11kV XLPE/PILC |

| SPAJ 12PX 185-300-3 | 3 Core 185-300sqmm | 11kV XLPE/PILC |

| SPAJ 12P 35-70-3 | 3 Core 35-70sqmm | 11kV PILC |

| SPAJ 12P 95-185-3 | 3 Core 95-185sqmm | 11kV PILC |

| SPAJ 12P 185-300-3 | 3 Core 185-300sqmm | 11kV PILC |

Heat Shrink Cable Joints

Test Technical Data

The following table provides an excerpt of data from the Type Test Reports for Heat Shrink Cable Joints for 6.6kV, 11kV and 33kV voltages.

| Summary of Cable Joint Test Voltages | ||||||

| Test | Test Voltage | Rated Voltage U01U (Um) kV | ||||

| 3.8/6.6 (7.2) | 6.35/11 (12) | 8.7/15 (17.5) | 12.7/22 (24) | 19/33 (36) | ||

| Humidity & Salt Fog | 1.25U0 | 5 | 8 | 11 | 16 | 24 |

| Partial Discharge | 1.73U0 | 6.5 | 11 | 15 | 22 | 33 |

| 2U0 | 7.5 | 12.5 | 17.5 | 25 | 38 | |

| Heating Cycle Voltage & AC Voltage / 15 min and 500 hours | 2.5U0 | 9.5 | 16 | 23 | 32 | 47.5 |

| AC Voltage / 1 min | 4U0 | 15 | 25.5 | 35 | 51 | 76 |

| AC Voltage / 5 min | 4.5U0 | 17 | 28.5 | 39 | 57 | 85.5 |

| DC Voltage / 15 min | 6U0 | 23 | 38 | 52 | 76 | 114 |

| Impulse (Peak) | – | 60 | 95 | 95 | 125 | 194 |

| Test Sequence & Requirements | ||||||

| Test | Test Clause of EN 61442 | Test Sequence | Test Requirements | |||

| A1 | A2 | A3 | ||||

| 1 | DC Voltage Dry | 5 | X | X | 15 min at 6U0, no breakdown or flashover | |

| 2 | AC Voltage Dry | 4 | X | X | 5 min at 4.5U0, no breakdown or flashover | |

| 3 | Partial Discharge At Ambient Temperature | 7 | X | Max 10pC at 1.73U0 | ||

| 4 | Impulse Voltage At Elevated Temperature | 6 | X | 10 impulses of each polarity, no breakdown or flashover | ||

| 5 | Heating Cycle Voltage In Air | 9 | X | 126 cycles at 2.5U0, no breakdown or flashover for terminations and 63 cycles in air and 63 cycles in water for cable joints | ||

| 6 | Partial Discharge At Elevated & Ambient Temperature | 7 | X | Max 10pC at 1.73U0 | ||

| 7 | Thermal Short Circuit (Screen) | 10 | X | 2 short circuits at 1sc no breakdown | ||

| 8 | Thermal Short Circuit (Conductor) | 11 | X | 2 short circuits to raise conductor to 6sc of the cable, no breakdown | ||

| 9 | Dynamic Short Circuit | 12 | X | 1 short circuit at 1d, no breakdown | ||

| 10 | Impulse Voltage At Ambient Temperature | 6 | X | X | 10 impulses of each polarity, no breakdown or flashover | |

| 11 | AC Voltage Dry | 4 | X | X | 15 min at 2.5U0, no breakdown or flashover | |

| 12 | Humidity | 13 | X | 300 hours duration at 1.25U0 | ||

| 13 | Examination | – | X | X | X | For information only |

Shrink Polymer Systems test and qualify their products to the criteria above as outlined in Cenelec standards HD 628 S1 and 629.1 S2:2006.

This testing criteria also encompasses VDE 0278 and IEC 60502.

Cable Joints for 11kV Medium Voltage Cables

Cable Joints For Paper Insulated Cables MV HV

Heat shrink cable joints are available for single-core and 3-core impregnated paper-insulated metal-sheathed cables that have copper or aluminium conductors and lead, lead alloy or corrugated seamless aluminium sheaths with rated voltages from 3,3/3,3kV up to 19/33kV.

- Impregnated, single-core paper cables – 3,8/6,6kV, 6,35/11kV, 12,7/22kV and 19/33kV

- Impregnated, single-core paper cables – 3,8/6,6kV and 6,35/11kV

- Impregnated, 3-core belted cables – 3,8/6,6kV, 6,6/6,6kV, 6,35/11kV and 11/11kV

- Impregnated, 3-core screened cables – 6,35/11kV, 12,7/22kV and 19/33kV

- Impregnated or drained, 3-core belted cables – 3,3/3,3kV, 3,8/6,6kV, 6,6/6,6kV, 6,35/11kV and 11/11kV

- Impregnated 3-core screened cables – 6,35/11kV

♦ See: HV Cable Terminations – Heat Shrink 6.6kV 11kV 33kV High Voltage Cables

➡ Should you require customer service or technical support to specify and select the correct cable joint please contact us – view the full range of HV Cable Joints below.

Heat Shrink Cable Joints For 11kV High/Medium Voltage Cables

Cable Terminations

To support the range of 11kV joints, T&D also distribute 11kV cable terminations for both indoor and outdoor use on underground and overhead power networks – typically used to connect high voltage power cables into air insulated switchgear/substations the heat shrink terminations provide excellent reliability, safety and availability from stock for immediate delivery:

- Stress Control & Anti-Tracking

- Electrical Insulation MV HV Terminations

- Adhesive Lined Moisture Protection Heat Shrink Tubings

- Excellent Mechanical Protection Of MV HV Cables

- Resist UV & Thermal Degradation

- Visit Joints, Terminations & Connectors MV HV

Thorne & Derrick distribute 3M, Pfisterer Connex, Nexans Euromold and Elastimold.