|

|

| home | contact | team t&d | group websites | markets | exports | blog |

|

|

3M 7600-T-3W Cold Shrink QT-III Cable Termination Indoor High Voltage

Cable Terminations QTIII - Indoor

Silicone Rubber 3 Core Cable Terminations

6.6kV 11kV 15kV 33kV IEC

3M 7600-T-3W

- Insulator Configuration - Tubular

- Installation Environment - Indoor

- Orientation - Normal

- For 3 Core Cable Type Without Ground Wires

3M 7600 Cold Shrink Series 3 Core (Three Conductor) Cable Terminations

3M Cold Shrink termination kits are designed to accomodate medium/high voltage 3 core shielded, copper tape screened or armoured power cables.

3M 7600-3W Cable Termination Kits using Cold Shrink for cables without ground wires and 3M 7600-RJS Termination Kits cabinet-mounted for cables with or without ground wires. With exception of high voltage cable lugs, which can be selected from the Cembre 2A Copper Cable Lugs range, each 3M Cold Shrink termination kit is supplied with all the materials required for terminating one 3 core (three conductor) cable.

3M 7600-3W Cold Shrink Termination Kit Contents

- Cold shrink silicone rubber cable breakout boot

- Silicone rubber phase re-jacketing sleeve

- Cold shrink silicone rubber cable termination

- Tinned copper earthing grounding braid

- Constant force springs

- 3M Scotch mastic seal strips

- 3M Scotch vinyl tape

- Cable cleaning and preparation kit

- High voltage HV cable jointers instruction

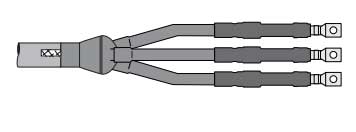

Pictured : 3M 7600-T-3W 3 Core Cold Shrink Cable Termination

3M Cold Shrink cable termination components include :

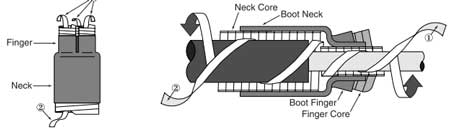

- Breakout Boot - an open ended moulded rubber sealing assembly that is factory expanded and mounted on removable inner supporting plastic cores. Breakout boots are supplied for field installation in a pre-stretched condition. The supporting cores are removed after the cold shrink boot has been positioned for installation around the breakout area of a 3 core cable. Core removal allows the silicone rubber boot to shrink down to a pre-determined diameter creating an environmental enclosure for individual cable phase legs and the cable jacket.

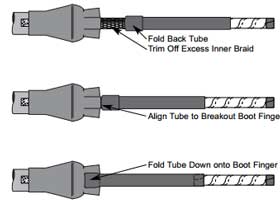

- Re-Jacketing Sleeve Assembly - a tubular silicone rubber insulating sleeve that incorporates an

inner expandable polyester braid designed to reduce sliding friction and deliver the cold shrink silicone tubing onto the cable phase metallic shielding. Re-jacketing sleeves are designed to protect the shielded high voltage cable phase legs from exposure to moisture, corrosion, ozone, ultra-violet radiation, physical contact and other hazards associated with cable termination operating environments.

inner expandable polyester braid designed to reduce sliding friction and deliver the cold shrink silicone tubing onto the cable phase metallic shielding. Re-jacketing sleeves are designed to protect the shielded high voltage cable phase legs from exposure to moisture, corrosion, ozone, ultra-violet radiation, physical contact and other hazards associated with cable termination operating environments.

3M Cold Shrink QT-III Cable Termination—a one-piece cold shrink assembly that consists of skirted or tubular insulator, high dielectric constant (Hi-K) stress control tube, conformable Hi-K stress control mastic and a built-in silicone cable lug sealing compound. The complete Cold Shrink assembly is pre-stretched and loaded onto a removable plastic core. Core removal allows the cable termination assembly to shrink down and seal onto prepared cable phase insulation and cable lug barrel surfaces.

Pictured : 3M RJS Re-Jacketing Sleeves Provide Cable Core Protection

3M Cold Shrink QT-III Cable Termination - Features and Benefits

- Versatile - cold shrink installs quickly and accommodates a wide range of high voltage power cable sizes

- Simple hand application - no need for special installation or cable jointing tools

- No gas torches or heat required - ideal for hazardous areas and potentially explosive atmospheres

- No specific user cable jointer skills or craftsmanship required

- Cold shrink demonstrates excellent resistance to ozone and ultra-violet radiation

- Good solvent resistance - compatible with industry approved cable cleaners

- Excellent thermal stability

- High dry and wet insulation resistance

- Highly flexible - accommodates all power cable bend radius recommendations

- Seals tight - cold shrink retains resiliency and pressure even after prolonged years of aging and exposure

3M Cold Shrink QT-III Cable Termination - Applications

3M 7600 Series QT-III Cold Shrink Cable Terminations are designed to accommodate three conductor (3 core) power cables ranging from No. 8 AWG (8sqmm) at 3kV to 500 KCMil (240sqmm) at 35kV.

Cold shrink terminations are compatible with the following solid dielectric insulation types : Polyethylene (high and low density), cross-linked Polyethylene (XLPE) and ethylene propylene rubber (EPR).

3M Cold Shrink cable terminations are light weight suitable for both free-hanging and bracket-mount, stand-off insulator type arrangements.

3M 7600 Cold Shrink Cable Terminations are available for both protected and weather-exposed areas. The amount of airborne contaminant determines the severity of the cable termination operating environment and may influence its long term performance. Operating environments are defined as light, medium, heavy and extremely heavy according to pollution severity. Selecting the appropriate termination depends on system voltage and operating environment.

3M Cold Shrink 7600 QT-III Cable Terminations - Technical Specification

- Electrical Ratings - 90 degrees Celsius continuous operating temperature, 130 degrees Celsius emergency overload (Class 1 designated to IEEE-48)

- Hydrophobicity - airborne contaminants deposited on cable termination surfaces can cause destructive leakage currents and discharge-initiated material erosion leading to high voltage tracking, flashover and cable failure. Hydrophobic silicone rubber and EPDM compounds provide Cold Shrink Terminations with a long service life under rain, fog and drizzle weather conditions

- Oxidation - silicone Cold Shrink resists ozone, corona and weathering

- Impulse Flashover - 3M QT-III cable terminations exceed IEEE Standard 48-1996 BIL by 50%

- Industrial Contamination - 3M cable terminations subject to intense and extreme chamber testing to determine tracking performance

- Dielectric Test - 3M Cold Shrink terminations conform to IEEE-48, CENELEC HD629.1 S1 and VDE 0278. 7 Pressure Leak Tests - excellent moisture sealed high voltage cable termination in accordance with IEEE-48-1996

3M Cold Shrink QT-III Cable Terminations - Impulse Flashover Testing Ratings

- T95 - 95kV BIL

- T110 - 110kV BIL

- T125 - 125kV BIL

- T150 - 150KV BIL

Pictured : Definition of Basic Insulation Level (BIL) via EEP

HV Cable Jointers Tips : Cinch constant force springs onto copper tape screen earth braid connection for effective bonded earth. View end of high voltage cable through finger cores to ease high voltage cable insertion. Spread cable phases while sliding cable boot breakout to ease the cable termination installation. Do not damage QT-III Cold Shrink termination while cutting RJS re-jacketing sleeve, sleeve assembly can be rotated to ease trimming. When high voltage cable lug spade dimension is larger than the inside diameter of the white plastic cable termination core, position the cable termination over cable phase legs prior to installing lugs. Do not push or pull the Cold Shrink termination while unwinding - continuously guide the Cold Shrink maintaining sleeve-to-cable-core alignment.

| 3M 7600-T-3W Cold Shrink Termination | Cable Insulation Range (mm) |

| 3M 7620-T95-3W | 8.40-12.7 |

| 3M 7621-T110-3W | 12.7-17.8 |

| 3M 7621-T95-3W | 12.7-17.8 |

| 3M 7622-T110-3W | 17.8-23.4 |

| 3M 7622-T125-3W | 17.8-23.4 |

| 3M 7623-T95-3W | 17.8-23.4 |

| 3M 7624-T110-3W | 23.4-30.0 |

| 3M 7624-T125-3W | 23.4-30.0 |

| 3M 7624-T95-3W | 23.4-30.0 |

| 3M 7625-T110-3W | 30-38.6 |

| 3M 7622-T125-3W | 17.8-23.4 |

| 3M 7623-T95-3W | 17.8-23.4 |

| 3M 7624-T110-3W | 23.4-30.0 |

| 3M 7624-T125-3W | 23.4-30.0 |

| 3M 7624-T95-3W | 23.4-30.0 |

| 3M 7693-T150-3W | 17.8-23.4 |

| 3M 7694-T150-3W | 23.4-30.0 |

| 3M 7695-T150-3W | 30.0-38.6 |

Video : 3M Cold Shrink Cable Terminations QT-III. 3M cable terminations shown terminating high voltage polymeric cables with copper tape screens.

| 3M Cold Shrink QT-III Indoor & Outdoor Cable Terminations Brochure |